|

|

PDF MMDF2C02HD Data sheet ( Hoja de datos )

| Número de pieza | MMDF2C02HD | |

| Descripción | COMPLEMENTARY DUAL TMOS POWER FET 2.0 AMPERES 20 VOLTS | |

| Fabricantes | Motorola Semiconductors | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de MMDF2C02HD (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MMDF2C02HD/D

™Designer's Data Sheet

Medium Power Surface Mount Products

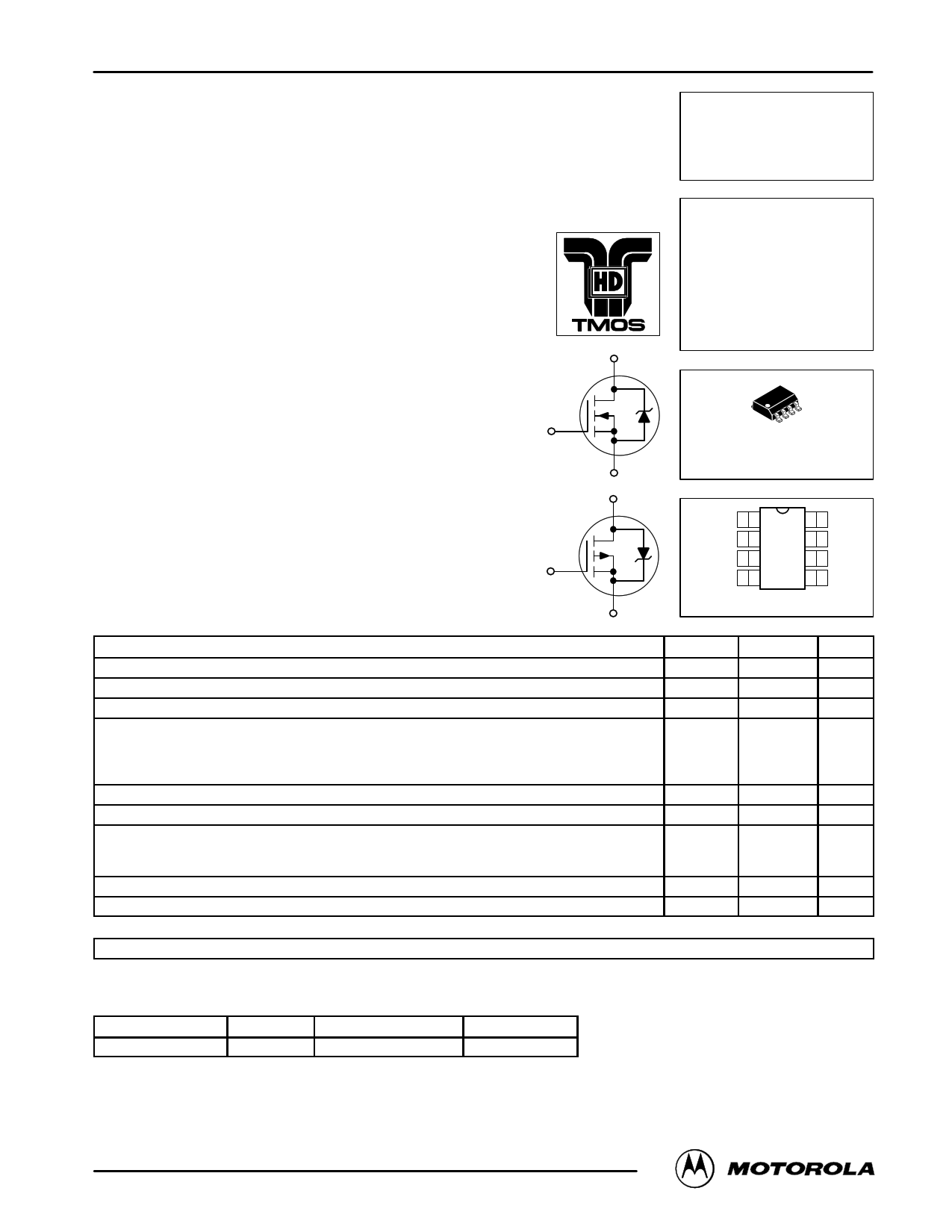

Complementary TMOS

Field Effect Transistors

MiniMOS™ devices are an advanced series of power MOSFETs

which utilize Motorola’s High Cell Density HDTMOS process.

These miniature surface mount MOSFETs feature ultra low RDS(on)

and true logic level performance. They are capable of withstanding

high energy in the avalanche and commutation modes and the

drain–to–source diode has a very low reverse recovery time.

MiniMOS devices are designed for use in low voltage, high speed

switching applications where power efficiency is important. Typical

applications are dc–dc converters, and power management in

portable and battery powered products such as computers,

printers, cellular and cordless phones. They can also be used for

low voltage motor controls in mass storage products such as disk

drives and tape drives. The avalanche energy is specified to

eliminate the guesswork in designs where inductive loads are

switched and offer additional safety margin against unexpected

voltage transients.

• Ultra Low RDS(on) Provides Higher Efficiency and Extends

Battery Life

• Logic Level Gate Drive — Can Be Driven by Logic ICs

• Miniature SO–8 Surface Mount Package — Saves Board Space

• Diode Is Characterized for Use In Bridge Circuits

• Diode Exhibits High Speed, With Soft Recovery

• Avalanche Energy Specified

• Mounting Information for SO–8 Package Provided

MAXIMUM RATINGS (TJ = 25°C unless otherwise noted)(1)

Rating

D

N–Channel

G

D

P–Channel

G

™

S

S

MMDF2C02HD

Motorola Preferred Device

COMPLEMENTARY

DUAL TMOS POWER FET

2.0 AMPERES

20 VOLTS

RDS(on) = 0.090 OHM

(N–CHANNEL)

RDS(on) = 0.160 OHM

(P–CHANNEL)

CASE 751–05, Style 14

SO–8

N–Source

N–Gate

P–Source

P–Gate

18

27

36

45

Top View

N–Drain

N–Drain

P–Drain

P–Drain

Symbol

Value

Unit

Drain–to–Source Voltage

Gate–to–Source Voltage

Drain–to–Gate Voltage (RGS = 1.0 mΩ)

Drain Current — Continuous

— Pulsed

N–Channel

P–Channel

N–Channel

P–Channel

Operating and Storage Temperature Range

Total Power Dissipation @ TA= 25°C (2)

Single Pulse Drain–to–Source Avalanche Energy — Starting TJ = 25°C

(VDD = 20 V, VGS = 5.0 V, Peak IL = 9.0 A, L = 10 mH, RG = 25 Ω)

(VDD = 20 V, VGS = 5.0 V, Peak IL = 6.0 A, L = 18 mH, RG = 25 Ω)

Thermal Resistance — Junction to Ambient (2)

N–Channel

P–Channel

Maximum Lead Temperature for Soldering, 0.0625″ from case. Time in Solder Bath is 10 seconds.

DEVICE MARKING

VDSS

VGS

VDGR

ID

IDM

TJ, Tstg

PD

EAS

RθJA

TL

20

± 20

20

3.8

3.3

19

20

– 55 to 150

2.0

405

324

62.5

260

Vdc

Vdc

Vdc

A

°C

Watts

mJ

°C/W

°C

D2C02

(1) Negative signs for P–Channel device omitted for clarity.

(2) Mounted on 2” square FR4 board (1” sq. 2 oz. Cu 0.06” thick single sided) with one die operating, 10 sec. max.

ORDERING INFORMATION

Device

Reel Size

Tape Width

Quantity

MMDF2C02HDR2

13″

12 mm embossed tape

2500 units

Designer’s Data for “Worst Case” Conditions — The Designer’s Data Sheet permits the design of most circuits entirely from the information presented. SOA Limit

curves — representing boundaries on device characteristics — are given to facilitate “worst case” design.

HDTMOS and MiniMOS are trademarks of Motorola, Inc. TMOS is a registered trademark of Motorola, Inc.

Thermal Clad is a trademark of the Bergquist Company.

Preferred devices are Motorola recommended choices for future use and best overall value.

REV 5

©MMoottoororolal,aInTc.M19O9S6 Power MOSFET Transistor Device Data

1

1 page

MMDF2C02HD

TYPICAL ELECTRICAL CHARACTERISTICS

N–Channel

P–Channel

1000

VGS = 0 V

100

VGS = 0 V

TJ = 125°C

100 TJ = 125°C

100°C

25°C

10

10

100°C

1

0 4 8 12 16 20

VDS, DRAIN–TO–SOURCE VOLTAGE (VOLTS)

Figure 6. Drain–To–Source Leakage

Current versus Voltage

1

0 5 10 15 20

VDS, DRAIN–TO–SOURCE VOLTAGE (VOLTS)

Figure 6. Drain–To–Source Leakage

Current versus Voltage

POWER MOSFET SWITCHING

Switching behavior is most easily modeled and predicted

by recognizing that the power MOSFET is charge controlled.

The lengths of various switching intervals (∆t) are deter-

mined by how fast the FET input capacitance can be charged

by current from the generator.

The published capacitance data is difficult to use for calculat-

ing rise and fall because drain–gate capacitance varies

greatly with applied voltage. Accordingly, gate charge data is

used. In most cases, a satisfactory estimate of average input

current (IG(AV)) can be made from a rudimentary analysis of

the drive circuit so that

t = Q/IG(AV)

During the rise and fall time interval when switching a resis-

tive load, VGS remains virtually constant at a level known as

the plateau voltage, VSGP. Therefore, rise and fall times may

be approximated by the following:

tr = Q2 x RG/(VGG – VGSP)

tf = Q2 x RG/VGSP

where

VGG = the gate drive voltage, which varies from zero to VGG

RG = the gate drive resistance

and Q2 and VGSP are read from the gate charge curve.

During the turn–on and turn–off delay times, gate current is

not constant. The simplest calculation uses appropriate val-

ues from the capacitance curves in a standard equation for

voltage change in an RC network. The equations are:

td(on) = RG Ciss In [VGG/(VGG – VGSP)]

td(off) = RG Ciss In (VGG/VGSP)

The capacitance (Ciss) is read from the capacitance curve at

a voltage corresponding to the off–state condition when cal-

culating td(on) and is read at a voltage corresponding to the

on–state when calculating td(off).

At high switching speeds, parasitic circuit elements com-

plicate the analysis. The inductance of the MOSFET source

lead, inside the package and in the circuit wiring which is

common to both the drain and gate current paths, produces a

voltage at the source which reduces the gate drive current.

The voltage is determined by Ldi/dt, but since di/dt is a func-

tion of drain current, the mathematical solution is complex.

The MOSFET output capacitance also complicates the

mathematics. And finally, MOSFETs have finite internal gate

resistance which effectively adds to the resistance of the

driving source, but the internal resistance is difficult to mea-

sure and, consequently, is not specified.

The resistive switching time variation versus gate resis-

tance (Figure 9) shows how typical switching performance is

affected by the parasitic circuit elements. If the parasitics

were not present, the slope of the curves would maintain a

value of unity regardless of the switching speed. The circuit

used to obtain the data is constructed to minimize common

inductance in the drain and gate circuit loops and is believed

readily achievable with board mounted components. Most

power electronic loads are inductive; the data in the figure is

taken with a resistive load, which approximates an optimally

snubbed inductive load. Power MOSFETs may be safely op-

erated into an inductive load; however, snubbing reduces

switching losses.

Motorola TMOS Power MOSFET Transistor Device Data

5

5 Page

MMDF2C02HD

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones and a figure

for belt speed. Taken together, these control settings make up

a heating “profile” for that particular circuit board. On

machines controlled by a computer, the computer remembers

these profiles from one operating session to the next. Figure

16 shows a typical heating profile for use when soldering a

surface mount device to a printed circuit board. This profile will

vary among soldering systems, but it is a good starting point.

Factors that can affect the profile include the type of soldering

system in use, density and types of components on the board,

type of solder used, and the type of board or substrate material

being used. This profile shows temperature versus time. The

line on the graph shows the actual temperature that might be

experienced on the surface of a test board at or near a central

solder joint. The two profiles are based on a high density and

a low density board. The Vitronics SMD310 convection/in-

frared reflow soldering system was used to generate this

profile. The type of solder used was 62/36/2 Tin Lead Silver

with a melting point between 177 –189°C. When this type of

furnace is used for solder reflow work, the circuit boards and

solder joints tend to heat first. The components on the board

are then heated by conduction. The circuit board, because it

has a large surface area, absorbs the thermal energy more

efficiently, then distributes this energy to the components.

Because of this effect, the main body of a component may be

up to 30 degrees cooler than the adjacent solder joints.

200°C

STEP 1

PREHEAT

ZONE 1

“RAMP”

STEP 2

VENT

“SOAK”

STEP 3

HEATING

ZONES 2 & 5

“RAMP”

STEP 4

STEP 5

HEATING HEATING

ZONES 3 & 6 ZONES 4 & 7

“SOAK”

“SPIKE”

DESIRED CURVE FOR HIGH

MASS ASSEMBLIES

160°C

170°C

STEP 6

VENT

STEP 7

COOLING

205° TO 219°C

PEAK AT

SOLDER JOINT

150°C

100°C

150°C

100°C

140°C

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

50°C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

Figure 16. Typical Solder Heating Profile

Motorola TMOS Power MOSFET Transistor Device Data

11

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet MMDF2C02HD.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MMDF2C02HD | COMPLEMENTARY DUAL TMOS POWER FET 2.0 AMPERES 20 VOLTS | Motorola Semiconductors |

| MMDF2C02HD | Power MOSFET ( Transistor ) | ON Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |