|

|

PDF MMFT107T1 Data sheet ( Hoja de datos )

| Número de pieza | MMFT107T1 | |

| Descripción | MEDIUM POWER TMOS FET 250 mA / 200 VOLTS | |

| Fabricantes | Motorola Semiconductors | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de MMFT107T1 (archivo pdf) en la parte inferior de esta página. Total 6 Páginas | ||

|

No Preview Available !

MOTOROLA

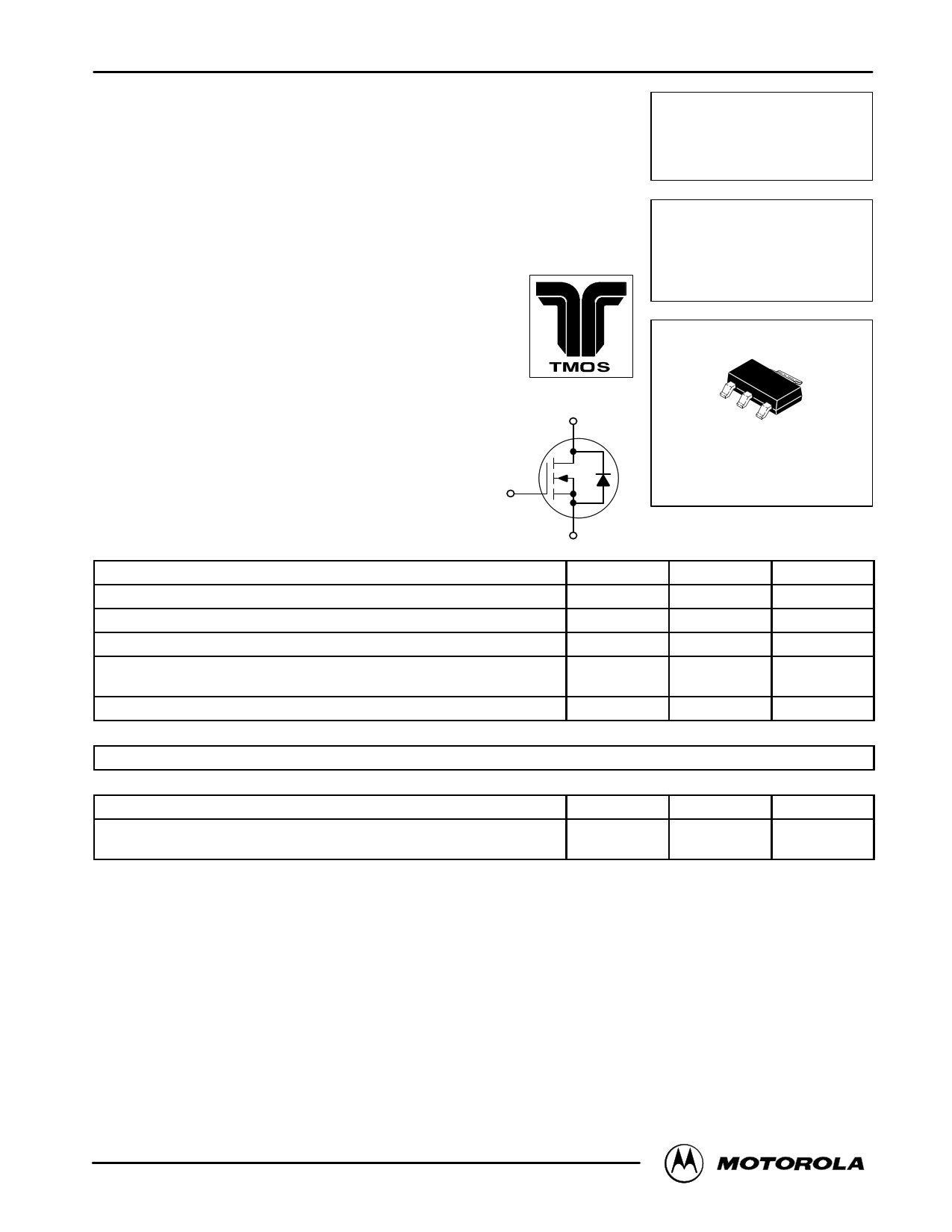

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MMFT107T1/D

Medium Power Field Effect

Transistor

N–Channel Enhancement–Mode

Silicon Gate TMOS

SOT–223 for Surface Mount

This TMOS medium power field effect transistor is designed for

high speed, low loss power switching applications such as

switching regulators, dc–dc converters, solenoid and relay drivers.

The device is housed in the SOT–223 package which is designed

for medium power surface mount applications.

• Silicon Gate for Fast Switching Speeds

• RDS(on) = 14 Ohm Max

• Low Drive Requirement

• The SOT–223 Package can be soldered using wave or reflow.

The formed leads absorb thermal stress during soldering

eliminating the possibility of damage to the die.

• Available in 12 mm Tape and Reel

Use MMFT107T1 to order the 7 inch/1000 unit reel

Use MMFT107T3 to order the 13 inch/4000 unit reel

1

GATE

®

2,4 DRAIN

MAXIMUM RATINGS (TC = 25°C unless otherwise noted)

Rating

3 SOURCE

Symbol

Drain–to–Source Voltage

Gate–to–Source Voltage — Non–Repetitive

Drain Current

Total Power Dissipation @ TA = 25°C(1)

Derate above 25°C

VDSS

VGS

ID

PD

Operating and Storage Temperature Range

DEVICE MARKING

TJ, Tstg

FT107

THERMAL CHARACTERISTICS

Thermal Resistance — Junction–to–Ambient

Maximum Temperature for Soldering Purposes

Time in Solder Bath

RθJA

TL

1. Device mounted on FR–4 glass epoxy printed circuit using minimum recommended footprint.

MMFT107T1

Motorola Preferred Device

MEDIUM POWER

TMOS FET

250 mA, 200 VOLTS

RDS(on) = 14 OHM MAX

1

2

3

4

CASE 318E–04, STYLE 3

TO–261AA

Value

200

± 20

250

0.8

6.4

– 65 to 150

Unit

Volts

Volts

mAdc

Watts

mW/°C

°C

156 °C/W

260 °C

10 Sec

TMOS is a registered trademark of Motorola, Inc.

Thermal Clad is a trademark of the Bergquist Company

Preferred devices are Motorola recommended choices for future use and best overall value.

REV 3

©MMoototorroollaa, ISncm. 1a9l9l–7Signal Transistors, FETs and Diodes Device Data

1

1 page

MMFT107T1

SOLDER STENCIL GUIDELINES

Prior to placing surface mount components onto a printed

circuit board, solder paste must be applied to the pads. A

solder stencil is required to screen the optimum amount of

solder paste onto the footprint. The stencil is made of brass

or stainless steel with a typical thickness of 0.008 inches.

The stencil opening size for the SOT-223 package should be

the same as the pad size on the printed circuit board, i.e., a

1:1 registration.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

• Always preheat the device.

• The delta temperature between the preheat and

soldering should be 100°C or less.*

• When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference should be a maximum of 10°C.

• The soldering temperature and time should not exceed

260°C for more than 10 seconds.

• When shifting from preheating to soldering, the

maximum temperature gradient should be 5°C or less.

• After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and result

in latent failure due to mechanical stress.

• Mechanical stress or shock should not be applied during

cooling

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.

TYPICAL SOLDER HEATING PROFILE

For any given circuit board, there will be a group of control

settings that will give the desired heat pattern. The operator

must set temperatures for several heating zones, and a

figure for belt speed. Taken together, these control settings

make up a heating “profile” for that particular circuit board.

On machines controlled by a computer, the computer

remembers these profiles from one operating session to the

next. Figure 10 shows a typical heating profile for use when

soldering a surface mount device to a printed circuit board.

This profile will vary among soldering systems but it is a good

starting point. Factors that can affect the profile include the

type of soldering system in use, density and types of

components on the board, type of solder used, and the type

of board or substrate material being used. This profile shows

temperature versus time. The line on the graph shows the

actual temperature that might be experienced on the surface

of a test board at or near a central solder joint. The two

profiles are based on a high density and a low density board.

The Vitronics SMD310 convection/infrared reflow soldering

system was used to generate this profile. The type of solder

used was 62/36/2 Tin Lead Silver with a melting point

between 177 –189°C. When this type of furnace is used for

solder reflow work, the circuit boards and solder joints tend to

heat first. The components on the board are then heated by

conduction. The circuit board, because it has a large surface

area, absorbs the thermal energy more efficiently, then

distributes this energy to the components. Because of this

effect, the main body of a component may be up to 30

degrees cooler than the adjacent solder joints.

200°C

STEP 1 STEP 2 STEP 3

STEP 4

STEP 5 STEP 6 STEP 7

PREHEAT VENT HEATING

HEATING HEATING VENT COOLING

ZONE 1

“RAMP”

“SOAK” ZONES 2 & 5 ZONES 3 & 6 ZONES 4 & 7

“RAMP”

“SOAK”

“SPIKE”

205° TO

219°C

DESIRED CURVE FOR HIGH

170°C

PEAK AT

MASS ASSEMBLIES

160°C

SOLDER

150°C

JOINT

150°C

100°C

100°C

140°C

SOLDER IS LIQUID FOR

40 TO 80 SECONDS

(DEPENDING ON

MASS OF ASSEMBLY)

DESIRED CURVE FOR LOW

MASS ASSEMBLIES

50°C

TIME (3 TO 7 MINUTES TOTAL)

TMAX

Figure 10. Typical Solder Heating Profile

Motorola Small–Signal Transistors, FETs and Diodes Device Data

5

5 Page | ||

| Páginas | Total 6 Páginas | |

| PDF Descargar | [ Datasheet MMFT107T1.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MMFT107T1 | MEDIUM POWER TMOS FET 250 mA / 200 VOLTS | Motorola Semiconductors |

| MMFT107T1 | Power MOSFET 250 mA / 200 Volts | ON |

| MMFT107T3 | Power MOSFET 250 mA / 200 Volts | ON |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |