|

|

PDF TORX193K Data sheet ( Hoja de datos )

| Número de pieza | TORX193K | |

| Descripción | FIBER OPTIC RECEIVING MODULE | |

| Fabricantes | Toshiba Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de TORX193K (archivo pdf) en la parte inferior de esta página. Total 7 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

FIBER OPTIC RECEIVING MODULE

TORX193K

FIBER OPTIC RECEIVING MODULE

FOR DIGITAL AUDIO EQUIPMENT

AND NAVIGATION SYSTEM

l Conform to JEITA Standard CP−1201 (For

Digital Audio Interfaces including Fiber

Optic inter−connections).

l TTL Interface

l ATC (Automatic Threshold Control) circuit is

used for stabilized output at a wide range of

optical power level.

TORX193K

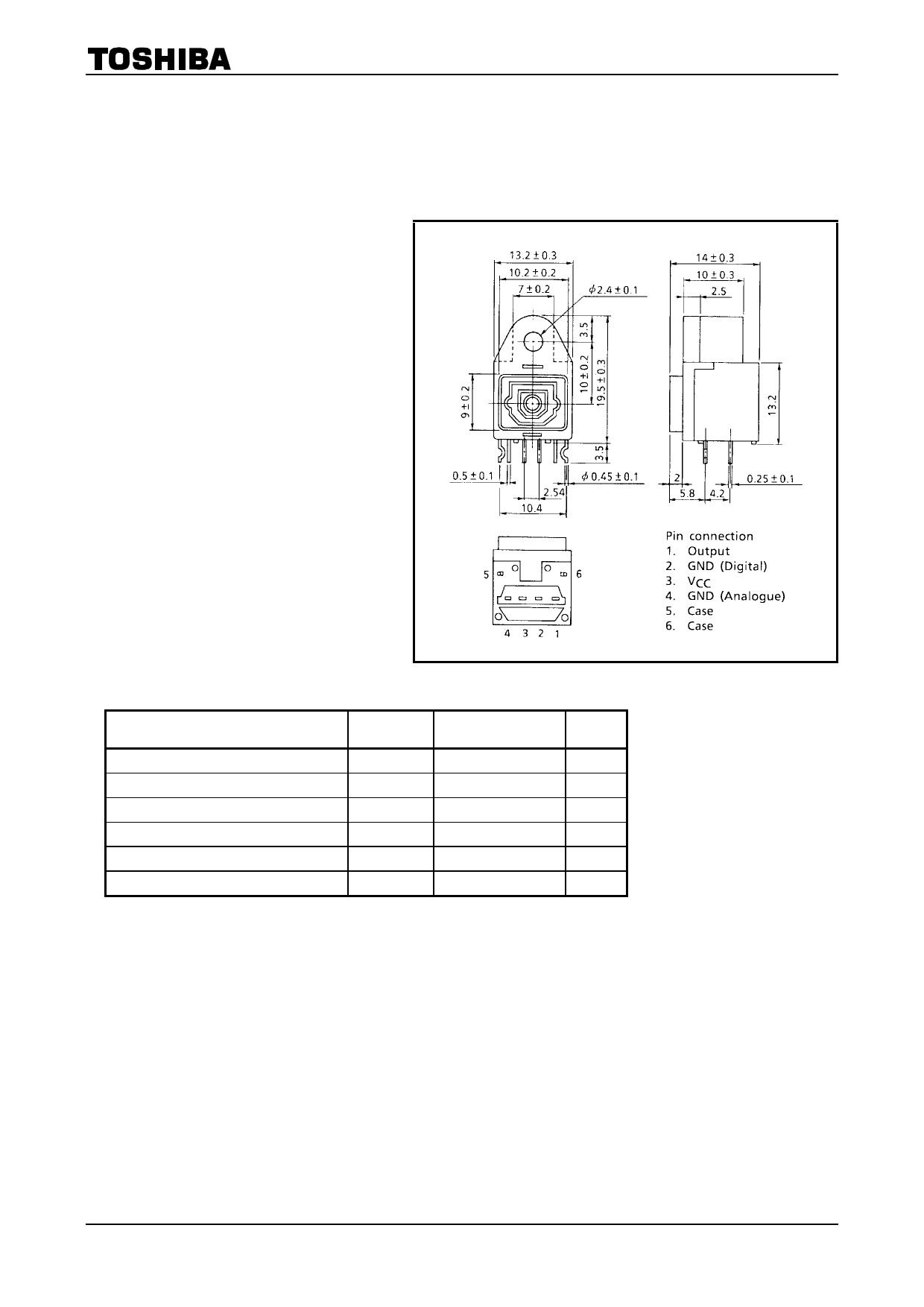

Unit: mm

1. Maximum Ratings (Ta = 25°C)

Characteristics

Symbol

Rating

Storage Temperature

Operating Temperature

Supply Voltage

Low Level Output Current

High Level Output Current

Soldering Temperature

Tstg

Topr

VCC

IOL

IOH

Tsol

−40 to 85

−40 to 85

−0.5 to 7

20

−1

260 (Note 1)

Note 1: Soldering time ≤ 10 s (More than 1 mm apart from the package).

Unit

°C

°C

V

mA

mA

°C

1 2001-08-10

1 page

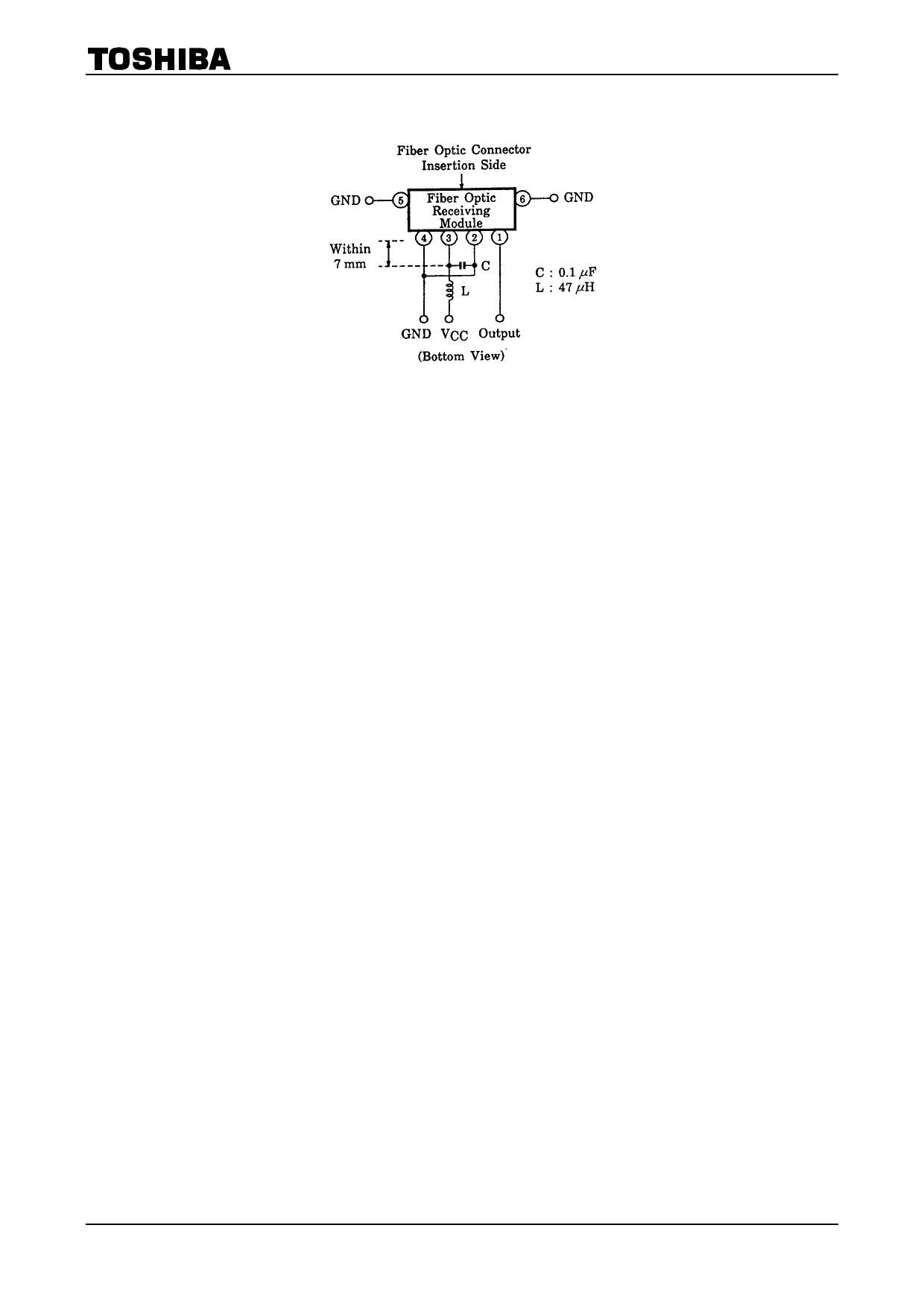

5. Application Circuit

TORX193K

6. Precautions during use

(1) Maximum rating

The maximum ratings are the limit values which must not be exceeded when using the device. Any

one of the rating must not be exceeded. If The maximum rating is exceeded, the characteristics may

not be recovered. In some extreme cases, the device may be permanently damage.

(2) Soldering

Optical modules use semiconductor devices internally. However, in principle, optical modules are

optical components. At soldering, take care that flux dose not contact the emitting surface or

detecting surface. Also take care at flux removal after soldering.

Some optical modules come with protective cap. The protective cap is used to avoid malfunction when

the optical module is not in use. Not that it is not dust or waterproof.

As mentioned before, optical modules are optical component. Thus, in principle, soldering where there

may be flux residue or flux removal after soldering is not recommended. Toshiba recommends that

soldering be performed without the optical module mounted on the board. Then, after the board is

cleaned, solder the optical module manually. Do not perform any further cleaning.

If the optical module cannot be soldered manually, use non−halogen (chlorine−free) flux and make

sure, without cleaning, there is no residue such as chlorine. This is one of the ways to eliminate the

effects of flux. In such a case, check the reliability.

(3) Noise resistance

Where the fiber optic receiving module case uses conductive resin, shield by connecting the

reinforcing pin at a front end of the module to GND. When using this optical module, connect the pin

to SIGNAL−GND.

Where the fiber optic receiving module case has a resistance of several tens of ohms, take care that

the case does not contact power line of other circuits.

It is believed that the use of optical transfer devices improve the noise resistance. In principle, optical

fiber is not affected by noise. However, especially receiving module which handle signals whose level

is extremely small, are comparatively more susceptible to noise.

TOSLINK improves noise resistance using a conductive case. However, the current of the signal

output from the photodiode of the optic receiving module is extremely small. Thus, depending on the

usage environment, shielding the case is not sufficient for noise resistance.

When using TOSLINK, Toshiba recommends that you test using the actual device and check the

noise resistance.

Use a simple noise filter on the TOSLINK fiber optic receiving module power line. If the ripple in

power supply used is high, further reinforce the filter.

When locating the optical module in an area susceptible to radiated noise, increase shielding by

covering the optical module and the power line filter using a metallic cover.

(4) Vibration and shock

This module is resin−molded construction with wire fixed by resin. This structure is relatively sound

against vibration or shock, In actual equipment, there are some cases where vibration, shock, and

stress is applied to soldered parts or connected parts, resultingin line cut. Attention must be paid to

the design of the mechanism for applications which are subject to large amounts of vibration.

5 2001-08-10

5 Page | ||

| Páginas | Total 7 Páginas | |

| PDF Descargar | [ Datasheet TORX193K.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| TORX193 | FIBER OPTIC RECEIVING MODULE | Toshiba Semiconductor |

| TORX193K | FIBER OPTIC RECEIVING MODULE | Toshiba Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |