|

|

PDF LT1210 Data sheet ( Hoja de datos )

| Número de pieza | LT1210 | |

| Descripción | 1.1A/ 35MHz Current Feedback Amplifier | |

| Fabricantes | Linear Technology | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de LT1210 (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

LT1210

1.1A, 35MHz Current

Feedback Amplifier

FEATURES

s 1.1A Minimum Output Drive Current

s 35MHz Bandwidth, AV = 2, RL = 10Ω

s 900V/µs Slew Rate, AV = 2, RL = 10Ω

s High Input Impedance: 10MΩ

s Wide Supply Range: ±5V to ±15V

(TO-220 and DD Packages)

s Enhanced θJA SO-16 Package for ±5V Operation

s Shutdown Mode: IS < 200µA

s Adjustable Supply Current

s Stable with CL = 10,000pF

APPLICATIONS

s Cable Drivers

s Buffers

s Test Equipment Amplifiers

s Video Amplifiers

s ADSL Drivers

U

TYPICAL APPLICATIO S

DESCRIPTIO

The LT®1210 is a current feedback amplifier with high

output current and excellent large-signal characteristics.

The combination of high slew rate, 1.1A output drive and

±15V operation enables the device to deliver significant

power at frequencies in the 1MHz to 2MHz range. Short-

circuit protection and thermal shutdown ensure the

device’s ruggedness. The LT1210 is stable with large

capacitive loads, and can easily supply the large currents

required by the capacitive loading. A shutdown feature

switches the device into a high impedance and low

supply current mode, reducing dissipation when the

device is not in use. For lower bandwidth applications,

the supply current can be reduced with a single external

resistor.

The LT1210 is available in the TO-220 and DD packages

for operation with supplies up to ±15V. For ±5V applica-

tions the device is also available in a low thermal resis-

tance SO-16 package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

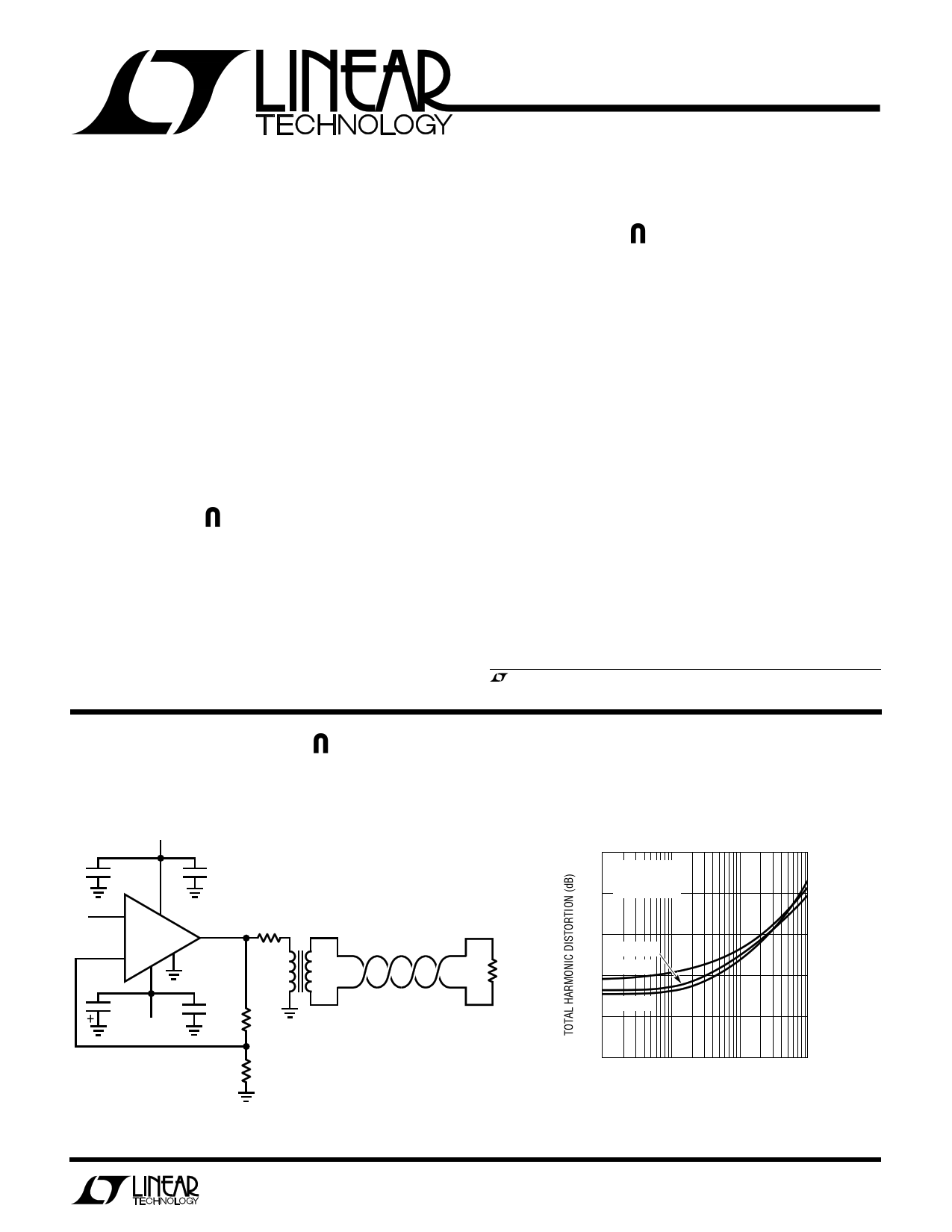

15V

+

4.7µF*

VIN +

LT1210

SD

–

+ 4.7µF*

–15V

Twisted Pair Driver

100nF

RT

11Ω

2.5W

T1**

13

RL

100Ω

2.5W

100nF

845Ω

274Ω

* TANTALUM

** MIDCOM 671-7783 OR EQUIVALENT

1210 TA01

Total Harmonic Distortion vs Frequency

–50

VS = ±15V

VOUT = 20VP-P

–60 AV = 4

–70

RL = 12.5Ω

–80 RL = 10Ω

RL = 50Ω

–90

–100

1k

10k 100k

FREQUENCY (Hz)

1M

1210 TA02

1

1 page

WU

TYPICAL PERFOR A CE CHARACTERISTICS

LT1210

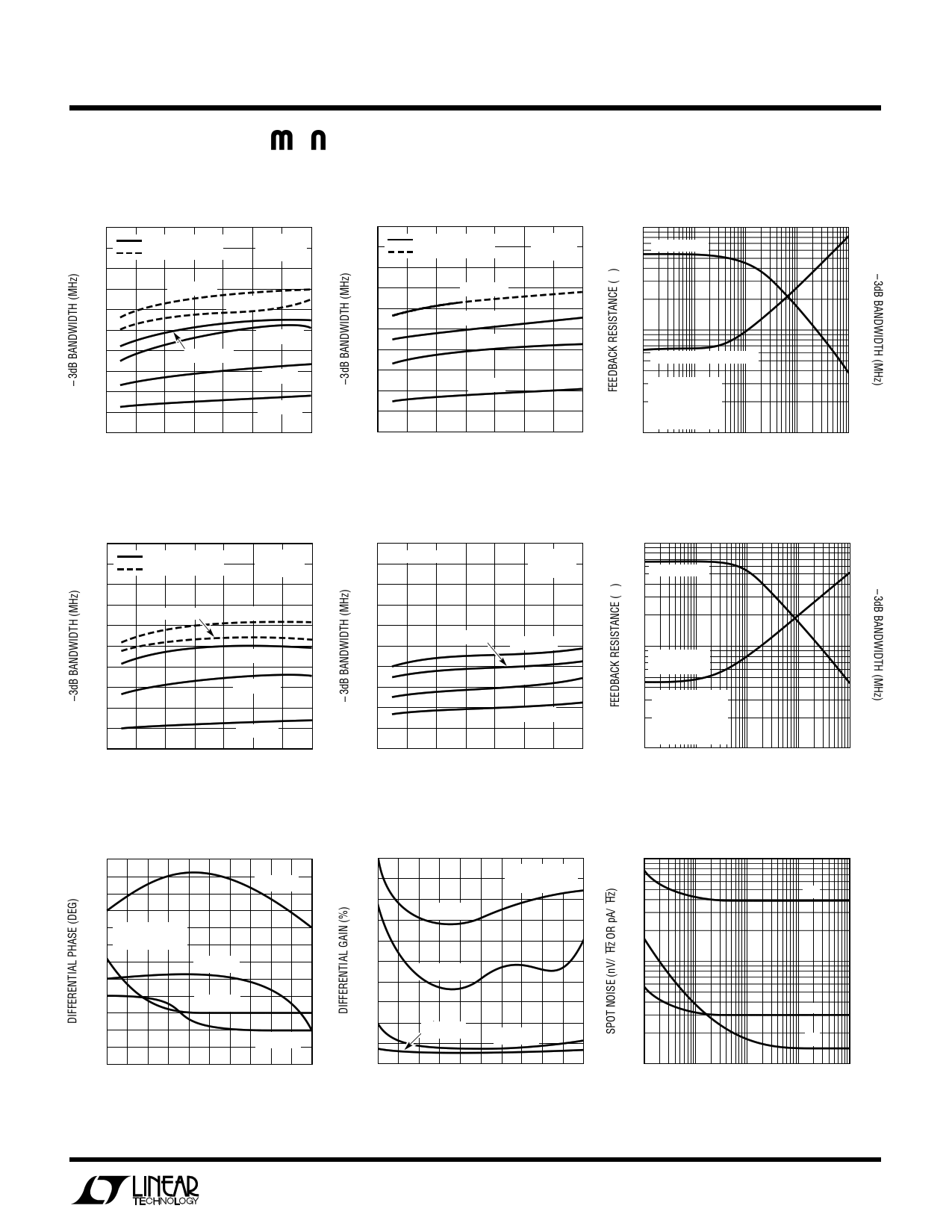

Bandwidth vs Supply Voltage

100

90

PEAKING ≤ 1dB

PEAKING ≤ 5dB

AV = 2

RL = 100Ω

80

70 RF = 470Ω

60 RF = 560Ω

50 RF = 750Ω

40 RF = 680Ω

30 RF = 1k

20

10 RF = 1.5k

0

4 6 8 10 12 14 16 18

SUPPLY VOLTAGE (±V)

1210 G01

Bandwidth vs Supply Voltage

100

90

PEAKING ≤ 1dB

PEAKING ≤ 5dB

AV = 10

RL = 100Ω

80

70

RF =390Ω

RF = 330Ω

60

50

RF = 470Ω

40

30 RF = 680Ω

20

10 RF = 1.5k

0

4 6 8 10 12 14 16 18

SUPPLY VOLTAGE (±V)

1210 G04

Differential Phase vs

Supply Voltage

0.6

0.5

RL = 10Ω

0.4 RF = RG = 750Ω

AV = 2

0.3 RL = 15Ω

0.2

0.1

0

5

RL = 50Ω

RL = 30Ω

7 9 11 13

SUPPLY VOLTAGE (±V)

15

1210 G07

Bandwidth vs Supply Voltage

50

PEAKING ≤ 1dB

PEAKING ≤ 5dB

40

AV = 2

RL = 10Ω

RF = 560Ω

30

RF = 750Ω

20 RF = 1k

10 RF = 2k

0

4 6 8 10 12 14 16 18

SUPPLY VOLTAGE (±V)

1210 G02

Bandwidth vs Supply Voltage

50

PEAKING ≤ 1dB

40

AV = 10

RL = 10Ω

Bandwidth and Feedback Resistance

vs Capacitive Load for Peaking ≤ 1dB

10k 100

BANDWIDTH

1k 10

FEEDBACK RESISTANCE

AV

RL

=

=

2

∞

VS = ±15V

CCOMP = 0.01µF

100

1 10

100

1000

CAPACITIVE LOAD (pF)

1

10000

1210 G03

Bandwidth and Feedback Resistance

vs Capacitive Load for Peaking ≤ 5dB

10k 100

BANDWIDTH

30

RF = 680Ω

RF = 560Ω

20

RF = 1k

10 RF = 1.5k

0

4 6 8 10 12 14 16 18

SUPPLY VOLTAGE (±V)

1210 G05

Differential Gain vs

Supply Voltage

0.5

0.4

RL = 10Ω

RF = RG = 750Ω

AV = 2

0.3

RL = 15Ω

0.2

0.1

0

5

RL = 50Ω

RL = 30Ω

7 9 11 13

SUPPLY VOLTAGE (±V)

15

1210 G08

1k

FEEDBACK

RESISTANCE

10

AV

RL

=

=

+2

∞

VS = ±15V

CCOMP = 0.01µF

100

1 10 100 1000

CAPACITIVE LOAD (pF)

1

10000

1210 G06

Spot Noise Voltage and Current

vs Frequency

100

– in

10

1

10

en

+in

100 1k 10k

FREQUENCY (Hz)

100k

1210 G09

5

5 Page

LT1210

APPLICATI S I FOR ATIO

Power Supplies

The LT1210 will operate from single or split supplies from

±5V (10V total) to ±15V (30V total). It is not necessary to

use equal value split supplies, however the offset voltage

and inverting input bias current will change. The offset

voltage changes about 500µV per volt of supply mis-

match. The inverting bias current can change as much as

5µA per volt of supply mismatch, though typically the

change is less than 0.5µA per volt.

Power Supply Bypassing

To obtain the maximum output and the minimum distor-

tion from the LT1210, the power supply rails should be

well bypassed. For example, with the output stage pouring

1A current peaks into the load, a 1Ω power supply imped-

ance will cause a droop of 1V, reducing the available

output swing by that amount. Surface mount tantalum and

ceramic capacitors make excellent low ESR bypass ele-

ments when placed close to the chip. For frequencies

above 100kHz, use 1µF and 100nF ceramic capacitors.

If significant power must be delivered below 100kHz,

capacitive reactance becomes the limiting factor. Larger

ceramic or tantalum capacitors, such as 4.7µF, are recom-

mended in place of the 1µF unit mentioned above.

Inadequate bypassing is evidenced by reduced output

swing and “distorted” clipping effects when the output is

driven to the rails. If this is observed, check the supply pins

of the device for ripple directly related to the output

waveform. Significant supply modulation indicates poor

bypassing.

Thermal Considerations

The LT1210 contains a thermal shutdown feature which

protects against excessive internal (junction) tempera-

ture. If the junction temperature of the device exceeds the

protection threshold, the device will begin cycling be-

tween normal operation and an off state. The cycling is not

harmful to the part. The thermal cycling occurs at a slow

rate, typically 10ms to several seconds, which depends on

the power dissipation and the thermal time constants of

the package and heat sinking. Raising the ambient tem-

perature until the device begins thermal shutdown gives a

good indication of how much margin there is in the

thermal design.

For surface mount devices heat sinking is accomplished

by using the heat spreading capabilities of the PC board

and its copper traces. Experiments have shown that the

heat spreading copper layer does not need to be electri-

cally connected to the tab of the device. The PCB material

can be very effective at transmitting heat between the pad

area attached to the tab of the device, and a ground or

power plane layer either inside or on the opposite side of

the board. Although the actual thermal resistance of the

PCB material is high, the length/area ratio of the thermal

resistance between the layer is small. Copper board stiff-

eners and plated through holes can also be used to spread

the heat generated by the device.

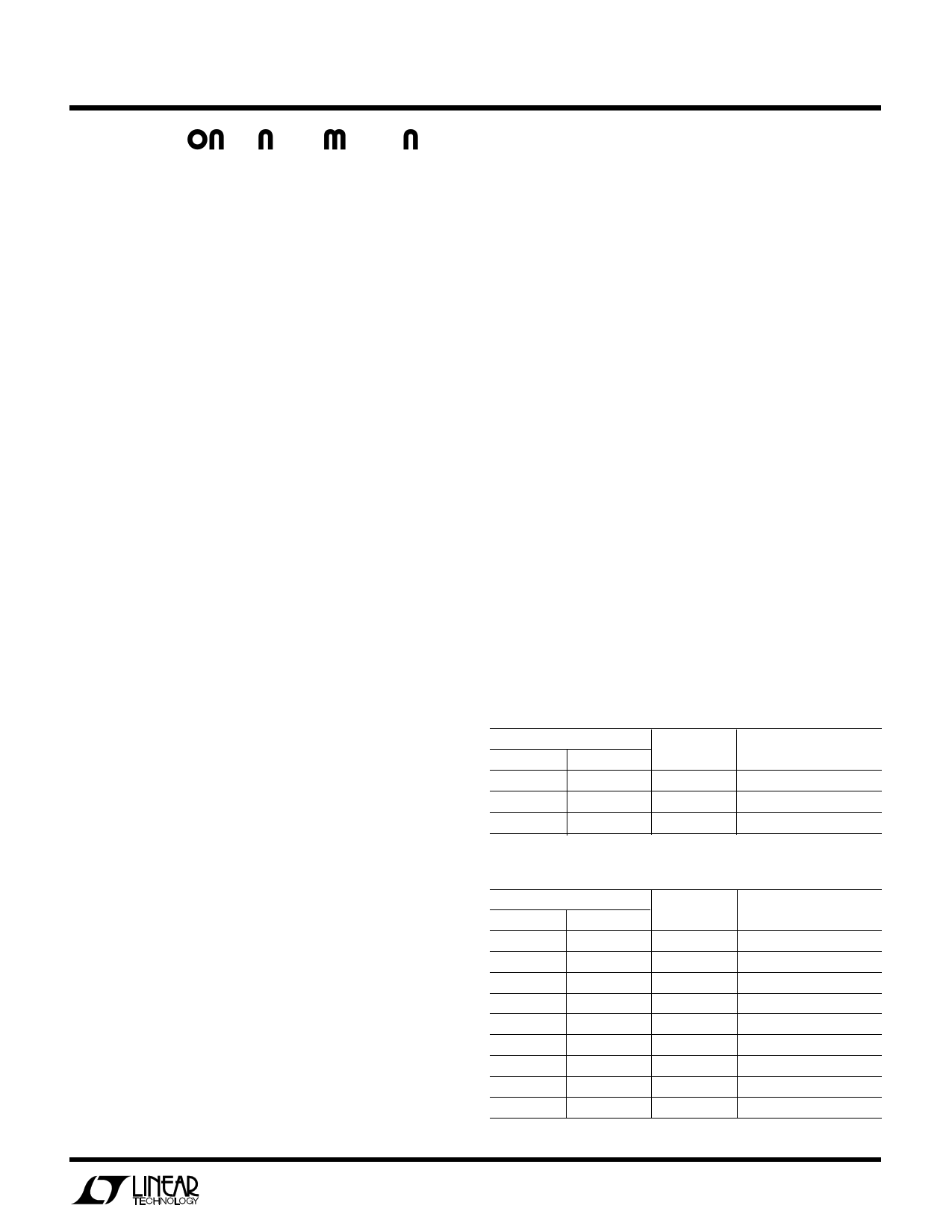

Tables 1 and 2 list thermal resistance for each package. For

the TO-220 package, thermal resistance is given for junc-

tion-to-case only since this package is usually mounted to

a heat sink. Measured values of thermal resistance for

several different board sizes and copper areas are listed for

each surface mount package. All measurements were

taken in still air on 3/32" FR-4 board with 2 oz copper. This

data can be used as a rough guideline in estimating

thermal resistance. The thermal resistance for each appli-

cation will be affected by thermal interactions with other

components as well as board size and shape.

Table 1. R Package, 7-Lead DD

COPPER AREA

TOPSIDE* BACKSIDE

2500 sq. mm 2500 sq. mm

1000 sq. mm 2500 sq. mm

125 sq. mm 2500 sq. mm

BOARD AREA

2500 sq. mm

2500 sq. mm

2500 sq. mm

THERMAL RESISTANCE

(JUNCTION-TO-AMBIENT)

25°C/W

27°C/W

35°C/W

*Tab of device attached to topside copper

Table 2. Fused 16-Lead SO Package

COPPER AREA

THERMAL RESISTANCE

TOPSIDE BACKSIDE BOARD AREA (JUNCTION-TO-AMBIENT)

2500 sq. mm 2500 sq. mm 5000 sq. mm

40°C/W

1000 sq. mm 2500 sq. mm 3500 sq. mm

46°C/W

600 sq. mm 2500 sq. mm 3100 sq. mm

48°C/W

180 sq. mm 2500 sq. mm 2680 sq. mm

49°C/W

180 sq. mm 1000 sq. mm 1180 sq. mm

56°C/W

180 sq. mm 600 sq. mm 780 sq. mm

58°C/W

180 sq. mm 300 sq. mm 480 sq. mm

59°C/W

180 sq. mm 100 sq. mm 280 sq. mm

60°C/W

180 sq. mm 0 sq. mm 180 sq. mm

61°C/W

11

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet LT1210.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LT1210 | 1.1A/ 35MHz Current Feedback Amplifier | Linear Technology |

| LT1210 | SMD Wire Wound Ferrite Chip Inductors | Chilisin Electronics |

| LT1210CR | 1.1A/ 35MHz Current Feedback Amplifier | Linear Technology |

| LT1210CS | 1.1A/ 35MHz Current Feedback Amplifier | Linear Technology |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |