|

|

PDF PFS725EG Data sheet ( Hoja de datos )

| Número de pieza | PFS725EG | |

| Descripción | (PFS704 - PFS729) High Power PFC Controller | |

| Fabricantes | Power Integrations | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de PFS725EG (archivo pdf) en la parte inferior de esta página. Total 30 Páginas | ||

|

No Preview Available !

PFS704-729EG

HiperPFS™ Family

High Power PFC Controller with Integrated

High-Voltage MOSFET

Key Benefits

• Single chip solution for boost power factor correction (PFC)

• EN61000-3-2 Class C and D compliant

• High light load efficiency at 10% and 20% load

• >95% efficiency from 10% load to full load

• <130 mW no-load consumption at 230 VAC with output in

regulation

• <50 mW no-load consumption at 230 VAC in remote off state

• Frequency adjusted over line voltage, and line cycle

• Spread-spectrum across >60 kHz window to simplify EMI

filtering requirements

• Lower boost inductance

• Provides up to 1 kW peak output power

• >1 kW peak power delivery in power limit voltage regulation

mode

• High integration allows smaller form factor, higher power density

designs

• Incorporates control, gate driver, and high-voltage power

MOSFET

• Internal current sense reduces component count and system

losses

• Protection features include: UV, OV, OTP, brown-in/out, cycle-

by-cycle current limit, and power limiting for overload protection

• Halogen free and RoHS compliant

Applications

• PC

• Printer

• LCD TV

• Video game consoles

• High power adaptors

• High power LED lighting

• Industrial and appliance

• Generic PFC converters

Output Power Table

Product

Maximum Continuous

Output Power Rating at

90 VAC

Peak Output Power

Rating at 90 VAC

PFS704EG

110 W

120 W

PFS706EG

PFS708EG

PFS710EG

PFS712EG

PFS714EG

PFS716EG

140 W

190 W

240 W

300 W

350 W

388 W

150 W

205 W

260 W

320 W

385 W

425 W

Product

Maximum Continuous

Output Power Rating at

180 VAC

Peak Output Power

Rating at 180 VAC

PFS723EG

PFS724EG

PFS725EG

PFS726EG

PFS727EG

PFS728EG

PFS729EG

255 W

315 W

435 W

540 W

675 W

810 W

900 W

280 W

350 W

480 W

600 W

750 W

900 W

1000 W

Table 1. Output Power Table (see Notes on page 9)

+

VCC

DV

VCC

AC

IN

HiperPFS

CONTROL

FB

SG

DC

OUT

www.powerint.com

Figure 1. Typical Application Schematic.

PI-6021-110810

December 2011

Free Datasheet http://www.datasheet4u.com/

1 page

PFS704-729EG

Functional Description

The HiperPFS is a variable switching frequency boost PFC

solution. More specifically, it employs a constant amp-second

on-time and constant volt-second off-time control algorithm.

This algorithm is used to regulate the output voltage and shape

the input current to comply with regulatory harmonic current

limits (high power factor). Integrating the switch current and

controlling it to have a constant amp-sec product over the

on-time of the switch allows the average input current to follow

the input voltage. Integrating the difference between the output

and input voltage maintains a constant volt-second balance

dictated by the electro-magnetic properties of the boost inductor

and thus regulates the output voltage and power.

VE

Latch

RESET

Latch

SET

Gate

Drive (Q)

Maximum

ON-time

Minimum

OFF-time

VOFF

IS dt

(VOUT-VIN)dt

Timing

Supervisor

More specifically, the control technique sets constant volt-

seconds

that:

for

the

off-time

(tOFF).

The off-time is controlled such

(1)

Since the volt-seconds during the on-time must equal the

volt-seconds during the off-time, to maintain flux equilibrium in

t he PFC c hoke, the on-time (tON) is co ntrolled s uch that:

(2)

The controller also sets a constant value of charge during each

on-cycle of the power MOSFET. The charge per cycle is varied

gradually over many switching cycles in response to load

changes so it can be regarded as substantially constant for a

half line cycle. With this constant charge (or amp-second)

control, the following relationship is therefore also true:

(3)

S ubstitutin g tON from (2) into (3) gives:

(4)

The relationship of (4) demonstrates that by controlling a constant

amp-second on-time and constant volt-second off-time, the input

cpurorrveidnitnIgIN tihsepfruonpdoarmtioennatlatlorethqeuirinepmuetnvtooltfapgoewVeINr,ftahcetorerfocorerrection.

Figure 4. Idealized Converter Waveforms.

cycle on-time. Internally the difference between the input and

output voltage is derived and the resultant is scaled, integrated,

and compared to a voltage reference (VOFF) to determine the

cycle off-time. Careful selection of the internal scaling factors

produce input current waveforms with very low distortion and

high power factor.

The input voltage is internally synthesized using the switch duty

cycle and a 7 kHz low pass filter. This synthesized input voltage

representation is subtracted from a fixed reference voltage (6 V)

to derive

Figure 3.

a

current

source

proportional

to

(VO-VIN).

Please refer to

TLhineeVFOeLeTdA-GFEorMwOarNdITSOcRal(iVng) pFinacctuorrre(nMt OisN)used internally to

derive the peak of the input line voltage which is used to scale

tThheisgcaoinntorfibtuhteiocnuirsrernetqsueirnesdetosigrendaul ctherothueghdythneamMicONravanrgiaebolef .the

control feedback signal as well maintain a constant loop gain

over the operating input line range. This line-sense feed-

forward gain adjustment is proportional to the square of the

peak rectified AC line voltage and is adjusted as a function of V

pin current. The line-sense feed-forward gain is also important

in providing a switch power limit over the input line range.

Besides modifying brown- in/out thresholds, the V pin resistor

also affects power limit of the device

This control produces a continuous mode power switch current

waveform that varies both in frequency and peak current value

across a line half-cycle to produce an input current proportional

to the input voltage.

Control Engine

The controller features a low bandwidth error-amplifier which

connects its non-inverting terminal to an internal voltage

reference of 6 V. The inverting terminal of the error-amplifier is

available on the external FEEDBACK pin which connects to the

external feedback resistor divider, transient load speed-up and

compensation networks to regulate the output voltage.

The internal sense-FET switch current is integrated and scaled

cboymthpeairnepduwt vitohlttahgeeeprreoar-kadmeptelicfietorrscigunrrael n(Vt Es)etnosdeegtearinm(iMneONth) eand

www.powerint.com

This characteristic is optimized to maintain a relatively constant

internal error-voltage level at full load from an input line of 100

to 230 VAC input (PFS704-716).

Beyond the specified peak power rating of the device, the

internal power limit feature will regulate the output voltage

below the set regulation threshold as a function of output

overload beyond the peak power rating. Figure 5 illustrates the

typical regulation characteristic as function of load.

Soft-Start with Pin-to-Pin Short-Circuit Protection

Since the FEEDBACK pin is the interface for output voltage

regulation (resistor voltage divider to output voltage) as well as

loop compensation (series RC), the typical application circuit of

the HiperPFS requires an external transistor network to overcome

the inherently slow feedback loop response. Specifically, an

5

Rev. D 12/11

Free Datasheet http://www.datasheet4u.com/

5 Page

PFS704-729EG

F1

3.15 A

L

R1

750 kΩ

D1

C3

220 nF

275 VAC

CAPZero

U2

CAP002DG

RV1

320 VAC

E D2

R2

750 kΩ

N

L1

10 mH

L2

100 µH

BR1

RT1

10 Ω

3KBP06M

600 V

tO

C19

220 nF

275 VAC

C4

100 pF

250 VAC

C5

100 pF

250 VAC

+

12 V

Auxiliary

Power

Supply

D1

1N5408

L5

1.7 mH

R4

1.5 MΩ

1%

D2

STTH3R06U

R9

1.5 MΩ

1%

R19

1.5 MΩ

1%

R11

732 kΩ

1%

C16

100 nF

200 V

C20

47 µF

25 V

R5

1 MΩ

1%

D4

1N4148

R10

1.6 MΩ

1%

C14

10 nF

1 kV

C7

470 nF

400 V

D

HiperPFS

U1

PFS708EG

S

C12

100 nF

50 V

V VCC

CONTROL

FB

R7

2 kΩ

Q1

MMBT4401

R15

160 kΩ

D3 R8

G

BAV116 3.01 kΩ

130 V

1%

R13

2.21 kΩ

1%

C11

10 nF

50 V

C18

1 µF

25 V

C13

4.7 µF

25 V

R14

57.6 kΩ

1%

R12

2.21 kΩ

1%

C17

470 pF

100 V

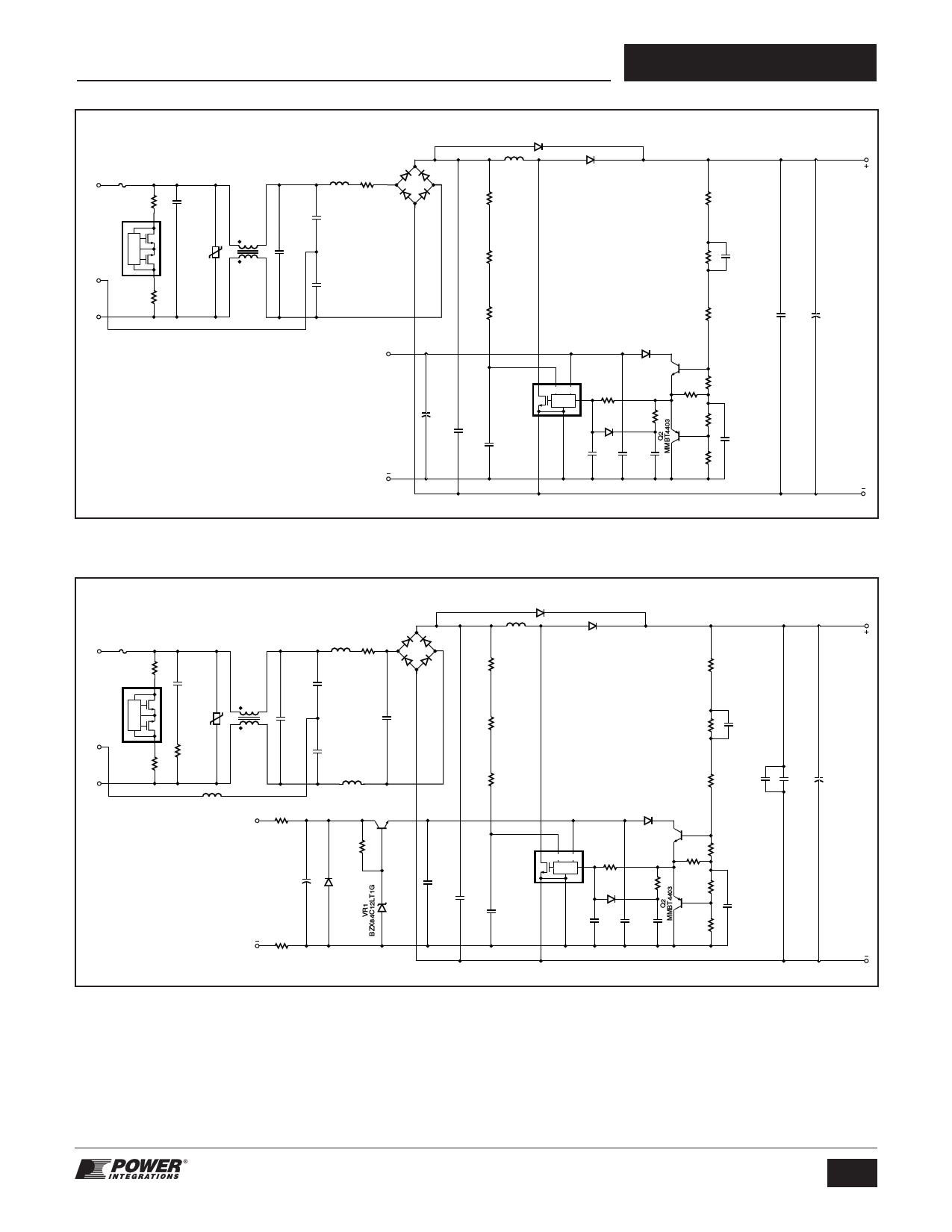

Figure 12. 180 W PFC using PFS708EG.

+

C15

150 µF

450 V

DC

OUT

PI-6229-110210

F1

8A

L

R1

220 kΩ

D1

CAPZero

U2

CAP006DG

E D2

R2

220 kΩ

N

C3

680 nF

275 VAC

RV1

320 VAC

R18

10 Ω

2W

L1

14 mH

L2

100 µH

BR1

RT1

10 Ω

GBU10J

600 V

tO

C19

1 µF

275 VAC

C4

680 pF

250 VAC

C6

100 nF

275 VAC

C5

680 pF

250 VAC

L4

Ferrite Bead

R6

100 Ω

+

15 V

Auxiliary

Power

Supply

C8

47 µF

50 V

L3

100 µH

Q3

MMBT4401LT1G

R17

3.01 kΩ

1%

D5

DL4001

R16

100 Ω

D1

1N5408

L5

2.04 mH

R4

3 MΩ

1%

D2

STTH12R06

R9

1.5 MΩ

1%

R19

3 MΩ

1%

R11

732 kΩ

1%

C16

100 nF

200 V

C20

100 nF

25 V

R5

3 MΩ

1%

R10

1.6 MΩ

1%

C21

10 nF

1 kV

D4

1N4148

C7

1.5 µF

400 V

D

HiperPFS

U1

PFS729EG

S

C12

47 nF

50 V

V VCC

CONTROL

FB

R7

2 kΩ

Q1

MMBT4401

R15

160 kΩ

D3 R8

G

BAV116 3.01 kΩ

130 V

1%

R13

2.21 kΩ

1%

C11

10 nF

50 V

C18

1 µF

25 V

C13

4.7 µF

25 V

R14

57.6 kΩ

1%

R12

2.21 kΩ

1%

C17

470 pF

100 V

Figure 13. 900 W PFC using PFS729EG.

+

C14

10 nF

1 kV

C15

820 µF

450 V

DC

OUT

PI-6230-111110

www.powerint.com

11

Rev. D 12/11

Free Datasheet http://www.datasheet4u.com/

11 Page | ||

| Páginas | Total 30 Páginas | |

| PDF Descargar | [ Datasheet PFS725EG.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| PFS725EG | (PFS704 - PFS729) High Power PFC Controller | Power Integrations |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |