|

|

PDF SP12352R7YLx-xxx Data sheet ( Hoja de datos )

| Número de pieza | SP12352R7YLx-xxx | |

| Descripción | Shielded SMD Power Inductor | |

| Fabricantes | ABC | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de SP12352R7YLx-xxx (archivo pdf) en la parte inferior de esta página. Total 5 Páginas | ||

|

No Preview Available !

SPECIFICATION FOR APPROVAL

REF. :

PROD.

NAME

Shielded SMD Power Inductor

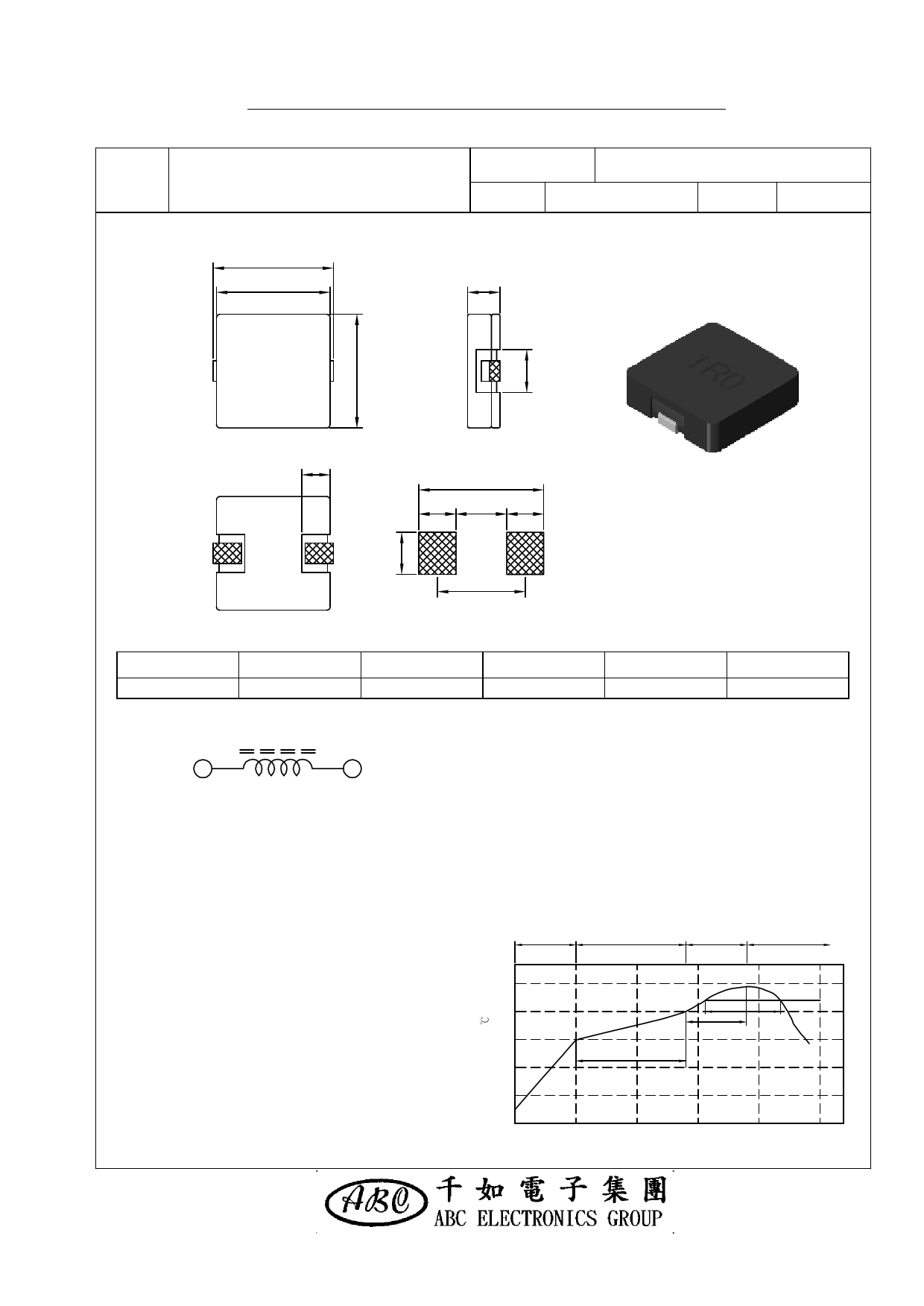

Ⅰ﹒Configuration and dimensions:

B'

B

ABC'S DWG NO.

SP1235□□□□L□-□□□

REV.

20130503-A

PAGE

1

C

E

13.6

4.0 5.6 4.0

A

12.70±0.30

B

12.70±0.30

Ⅱ﹒Schematic diagram:

9.6

( PCB Pattern )

B'

13.00±0.30

C

3.50±0.30

D

4.20 typ.

Unit:m/m

E

3.30 typ.

12

Ⅲ﹒Description:

a﹒Ferrite ER core construction.

b﹒Magnetically shielded.

c﹒Enamelled copper wire:F class

d﹒Product weight: 3.10 g(ref.)

e﹒Moisture sensitivity Level 1

f﹒Products comply with RoHS' requirements

g﹒Halogen free available

Ⅳ﹒General specification:

a﹒Storage temp.:-55℃ ~ +125℃

b﹒Operating temp .:-55℃ ~ +125℃

( Temp. rise included )

c﹒Resistance to solder heat:245℃. 10 secs.

AR-001C

Temperature

Rising Area

+4.0℃ / sec max.

250

200

150

100

Peak Temp:245℃ max.

Max. Peak Temp - 5℃:30sec max.

Max time above 217℃ :60sec~150sec max.

Preheat Area

150 ~ 200℃ / 60 ~ 120sec

Reflow Area Forced Cooling Area

+3.0℃ / sec max. -(1.0 ~ 5.0)℃ / sec max.

Peak Temperature:

245℃

60sec~150sec

60sec max.

217℃

60sec~120sec

50

0 50 100 150 200 250

Time ( seconds )

Free Datasheet http://www.datasheet4u.com/

1 page

SPECIFICATION FOR APPROVAL

REF. :

PROD.

NAME

Shielded SMD Power Inductor

Ⅶ﹒Reliability test:

ABC'S DWG NO.

SP1235□□□□L□-□□□

REV.

20130503-A

PAGE

5

Item Reference documents

Test Condition

Test Specification

1.High Temperature

Exposure

MIL-STD-202 Method 108 1.Temperature: 125℃

2.Time:96 hours.

2.Temperature Cycling JESD22 Method JA-104

1.Temperature: -55℃ ~ 125℃

2.Number of cycle:96 cycle

3.Dwell time:30 minutes

1.Temperature: 85±5 ℃

3.Biased Humidity Test MIL-STD-202 Method 103 2.Time:96 Hours

3.Humidity: 85±5% RH.

4.Operational Life

MIL-PRF-27

1.Temperature: 125℃

2.Time:96 hours.

3.Apply rated current.

5.Exeternal Visual

Inspect product

MIL-STD-883 Method 2009 constructions, marking and

workmanship.

6.Physical Dimensions JESD22 Method JB-100

Verify physical dimensions to

the applicable product detail

specification.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.No pollution on the surface of

products.

2.Clear marking.

3.No crack.

Per product specification

standard

7.Resistance to solvents MIL-STD-202 Method 215

8.Vibration Test

MIL-STD-202 Method 204

9.Resistance To

Soldering Heat Test

MIL-STD-202 Method 210

10.Rated current

MIL-STD-202 Method 330

11.Temperature rise MIL-PRF-27

12.Over load

MIL-PRF-27

13.Solderability Test J-STD-002

14.Electrical

Characteriazation

15.Withstanding

Voltage Test

User Spec.

MIL-STD-202 Method 201

16.Drop

JESD22-B111

17.Terminal Strength

Test

JIS-C-6429

Immerse into solvent for 3±0.5 minutes &

brush 10 times for therr cycles.

1.No body change in apperarance.

2.No marking blurred.

3.Inductance shall not change

more than ±25%.

1.Frequency and Amplitued :

10-2000-10 Hz, 1.5 mm.

2.Direction:X, Y, Z

3.Test duration:2 hours for each direction,

6 hours in total.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.Highest temperature:245±5℃

2.Time(temp.≧ 217℃):60~150 Second.

3.IR reflow times:3 times.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

Apply rated current for 5 second.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

Apply rated current for 10 minutes.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.No mechanical and electrical

Apply twice as rated current for 5 minutes. damage.

(It's not application to some special design) 2.Inductance shall not change

more than ±25%.

1.Baking in pre-testing:

155±5℃ / 16Hours±30 min.

2.Peak temperature:240±5℃

3.Time(temp.≧217℃):60~150 second.

4.IR reflow times:1 times.

The terminal shall be at least 95%

covered with fresh solder.

1.Operating temperature: -55℃~125℃

2.Room temperature:25℃.

1.No mechanical and electrical

damage.

2.Inductance shall not change

more than ±25%.

1.DV:500V

2.Time:1minutes

1.During the test no breakdown.

2.The characteristic is normal after test.

Packaged & Drop down from 1m.In 1 angle

1ridges & 2 surfaces orientation.

1.No case deformation or change in

appearance.

2.Inductance shall not change

more than ±25%.

1.Apply push force to samples

mounted on PCB.

2.Force of 1.8 kg for 60±1 seconds.

After test, inductors shall be no

mechanical damage.

AR-001A

Free Datasheet http://www.datasheet4u.com/

5 Page | ||

| Páginas | Total 5 Páginas | |

| PDF Descargar | [ Datasheet SP12352R7YLx-xxx.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| SP12352R7YLx-xxx | Shielded SMD Power Inductor | ABC |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |