|

|

PDF A4986 Data sheet ( Hoja de datos )

| Número de pieza | A4986 | |

| Descripción | DMOS Dual Full-Bridge PWM Motor Driver | |

| Fabricantes | Allegro MicroSystems | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de A4986 (archivo pdf) en la parte inferior de esta página. Total 14 Páginas | ||

|

No Preview Available !

A4986

DMOS Dual Full-Bridge PWM Motor Driver

with Overcurrent Protection

Features and Benefits

▪ Low RDS(ON) outputs

▪ Internal mixed current decay mode

▪ Synchronous rectification for low power dissipation

▪ Internal UVLO

▪ Crossover-current protection

▪ 3.3 and 5 V compatible logic supply

▪ Thin profile QFN and TSSOP packages

▪ Thermal shutdown circuitry

▪ Short-to-ground protection

▪ Shorted load protection

▪ Low current Sleep mode, < 10 μA

Package:

24-pin TSSOP

with exposed thermal pad

(LP Package)

Approximate size

Description

The A4986 is a dual DMOS full-bridge stepper motor driver

with parallel input communication and overcurrent protection.

Each full-bridge output is rated up to 35 V and ±2 A.

The A4986 includes fixed off-time pulse width modulation

(PWM) current regulators, along with 2- bit nonlinear DACs

(digital-to-analog converters) that allow stepper motors to be

controlled in full, half, and quarter steps. The PWM current

regulator uses the Allegro® patented mixed decay mode for

reduced audible motor noise, increased step accuracy, and

reduced power dissipation.

Internal synchronous rectification control circuitry is provided

to improve power dissipation during PWM operation.

The outputs are protected from shorted load and short-to-

ground events, which protect the driver and associated circuitry

from thermal damage or flare-ups. Other protection features

include thermal shutdown with hysteresis, undervoltage lockout

(UVLO) and crossover current protection. Special power-up

sequencing is not required.

The A4986 is supplied in a 24-pin TSSOP (LP) with exposed

thermal pad for enhanced thermal performance. It has a

0.65 pitch and an overall package height of ≤1.2 mm. It is lead

(Pb) free, with 100% matte tin leadframe plating.

Typical Application Diagram

Microcontroller or

Controller Logic

VDD

0.22 μF

0.1 μF

0.1 μF

0.22 μF

VREG ROSC CP1

VDD

CP2

VCP VBB1

VBB2

SLEEP

IN01

IN02

PH1

IN11

IN12

PH2

VREF

A4986

OUT1A

OUT1B

SENSE1

GND

OUT2A

GND

OUT2B

SENSE2

100 μF

4986-DS

1 page

A4986

DMOS Dual Full-Bridge PWM Motor Driver

with Overcurrent Protection

THERMAL CHARACTERISTICS may require derating at maximum conditions

Characteristic

Symbol

Test Conditions*

Package Thermal Resistance

RθJA LP package; on 4-layer PCB, based on JEDEC standard

*In still air. Additional thermal information available on Allegro Web site.

Value Units

28 ºC/W

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

20

Maximum Power Dissipation, PD(max)

(R

θJA = 28 ºC/W)

40 60 80 100 120 140 160 180

Temperature (°C)

Allegro MicroSystems, Inc.

5

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5 Page

A4986

DMOS Dual Full-Bridge PWM Motor Driver

with Overcurrent Protection

100.0

66.7

Phase 1

(%)

0

–66.7

–100.0

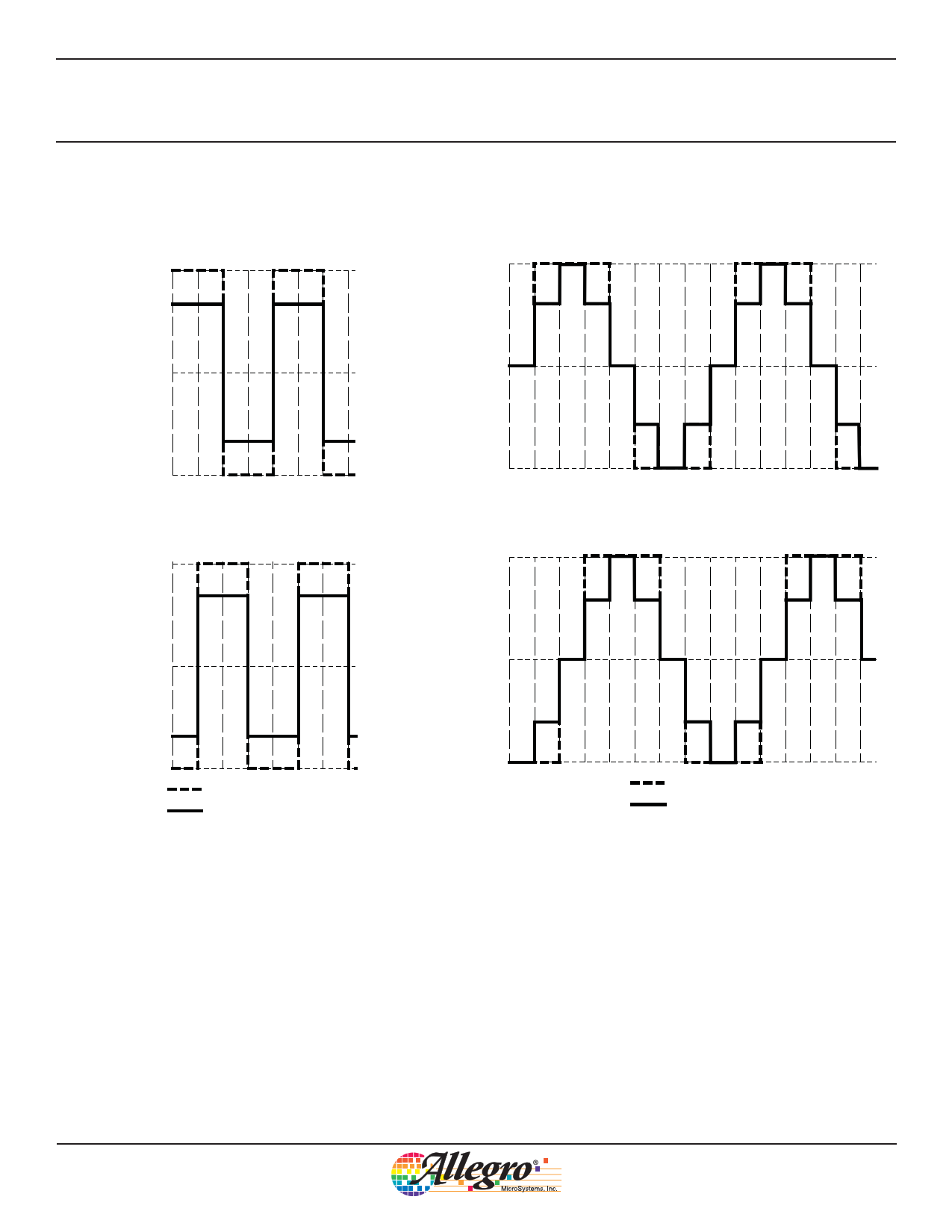

Step Sequencing Diagrams

100.0

66.7

Phase 1

(%)

0

–66.7

–100.0

100.0

66.7

Phase 2

(%)

0

–66.7

–100.0

Full step 2 phase

Modified full step 2 phase

100.0

66.7

Phase 2

(%)

0

–66.7

–100.0

Half step 2 phase

Modified half step 2 phase

Figure 5. Step Sequencing for Full-Step Increments.

Figure 6. Step Sequencing for Half-Step Increments.

Allegro MicroSystems, Inc.

11

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11 Page | ||

| Páginas | Total 14 Páginas | |

| PDF Descargar | [ Datasheet A4986.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| A4983 | DMOS Microstepping Driver | Allegro MicroSystems |

| A4986 | DMOS Dual Full-Bridge PWM Motor Driver | Allegro MicroSystems |

| A4988 | DMOS Microstepping Driver | Allegro |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |