|

|

PDF MGSF3454XT1 Data sheet ( Hoja de datos )

| Número de pieza | MGSF3454XT1 | |

| Descripción | Small-Signal MOSFETs Single N-Channel Field Effect Transistors | |

| Fabricantes | ON Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de MGSF3454XT1 (archivo pdf) en la parte inferior de esta página. Total 6 Páginas | ||

|

No Preview Available !

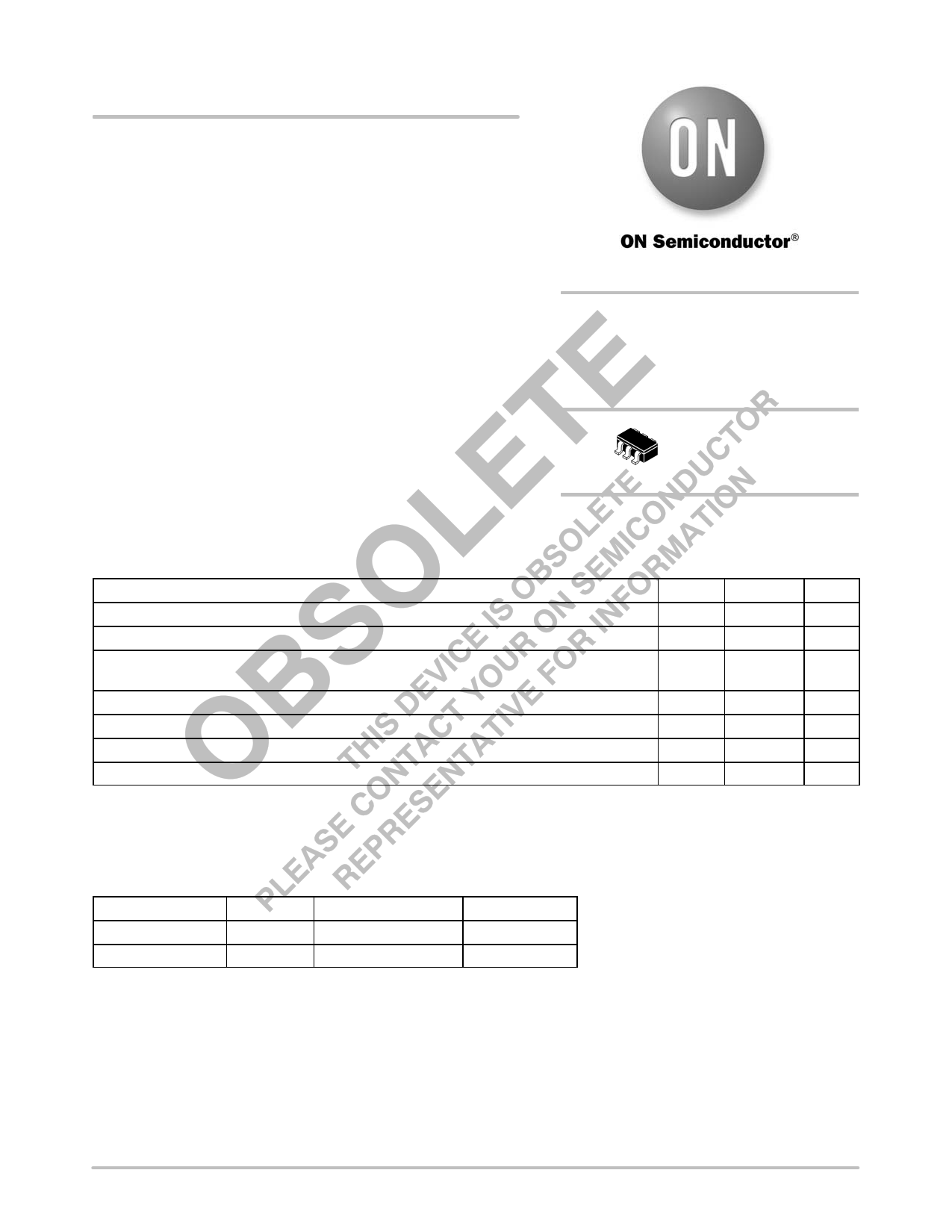

MGSF3454XT1

Product Preview

Low RDS(on) Small-Signal

MOSFETs Single N-Channel

Field Effect Transistors

These miniature surface mount MOSFETs utilize the High Cell

Density, HDTMOS® process. Low RDS(on) assures minimal power

loss and conserves energy, making this device ideal for use in small

power management circuitry. Typical applications are dc−dc

converters, power management in portable and battery−powered

products such as computers, printers, PCMCIA cards, cellular and

cordless telephones.

• Low RDS(on) Provides Higher Efficiency and Extends Battery Life

• Miniature TSOP−6 Surface Mount Package Saves Board Space

http://onsemi.com

N−CHANNEL

ENHANCEMENT−MODE

MOSFET

RDS(on) = 50 mW (TYP)

DD S

DDG

CASE 318G−02, Style 1

TSOP 6 PLASTIC

MAXIMUM RATINGS (TJ = 25°C unless otherwise noted)

Rating

Symbol

Value

Unit

Drain−to−Source Voltage

Gate−to−Source Voltage − Continuous

Drain Current − Continuous @ TA = 25°C

Drain Current − Pulsed Drain Current (tp ≤ 10 ms)

VDSS

VGS

ID

IDM

30

± 20

1.75

20

Vdc

Vdc

A

Total Power Dissipation @ TA = 25°C

PD 950 mW

Operating and Storage Temperature Range

TJ, Tstg −55 to 150

°C

Thermal Resistance − Junction−to−Ambient

RqJA

250 °C/W

Maximum Lead Temperature for Soldering Purposes, for 10 seconds

TL 260 °C

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

Device Marking = 3G

Device

MGSF3454XT1

MGSF3454XT3

ORDERING INFORMATION

Reel Size

Tape Width

7″ 8 mm embossed tape

13″ 8 mm embossed tape

Quantity

3000

10,000

This document contains information on a product under development. ON Semiconductor

reserves the right to change or discontinue this product without notice.

© Semiconductor Components Industries, LLC, 2013

May, 2013 − Rev. 1

1

Publication Order Number:

MGSF3454XT1/D

1 page

MGSF3454XT1

INFORMATION FOR USING THE TSOP−6 SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINT FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must

be the correct size to insure proper solder connection

interface between the board and the package. With the

correct pad geometry, the packages will self align when

subjected to a solder reflow process.

0.094

2.4

0.037

0.95

0.074

1.9

0.037

0.95

0.039

1.0

TSOP−6

0.028

0.7

inches

mm

TSOP−6 POWER DISSIPATION

The power dissipation of the TSOP−6 is a function of the

drain pad size. This can vary from the minimum pad size for

soldering to a pad size given for maximum power

dissipation. Power dissipation for a surface mount device is

determined by TJ(max), the maximum rated junction

temperature of the die, RqJA, the thermal resistance from

the device junction to ambient, and the operating

temperature, TA. Using the values provided on the data

sheet for the TSOP−6 package, PD can be calculated as

follows:

PD =

TJ(max) − TA

RqJA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values

into the equation for an ambient temperature TA of 25°C,

one can calculate the power dissipation of the device which

in this case is 500 milliwatts.

PD =

150°C − 25°C

250°C/W

= 500 milliwatts

The 250°C/W for the TSOP−6 package assumes the use

of the recommended footprint on a glass epoxy printed

circuit board to achieve a power dissipation of 500

milliwatts. There are other alternatives to achieving higher

power dissipation from the TSOP−6 package. Another

alternative would be to use a ceramic substrate or an

aluminum core board such as Thermal Clad™. Using a

board material such as Thermal Clad, an aluminum core

board, the power dissipation can be doubled using the

same footprint.

SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

• Always preheat the device.

• The delta temperature between the preheat and

soldering should be 100°C or less.*

• When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference shall be a maximum of 10°C.

• The soldering temperature and time shall not exceed

260°C for more than 10 seconds.

• When shifting from preheating to soldering, the

maximum temperature gradient shall be 5°C or less.

• After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and

result in latent failure due to mechanical stress.

• Mechanical stress or shock should not be applied

during cooling.

* Soldering a device without preheating can cause

excessive thermal shock and stress which can result in

damage to the device.

http://onsemi.com

5

5 Page | ||

| Páginas | Total 6 Páginas | |

| PDF Descargar | [ Datasheet MGSF3454XT1.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| MGSF3454XT1 | N-CHANNEL ENHANCEMENT-MODE TMOS MOSFET | Motorola Semiconductors |

| MGSF3454XT1 | Small-Signal MOSFETs Single N-Channel Field Effect Transistors | ON Semiconductor |

| MGSF3454XT3 | Small-Signal MOSFETs Single N-Channel Field Effect Transistors | ON Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |