|

|

PDF ISL97649AR5566 Data sheet ( Hoja de datos )

| Número de pieza | ISL97649AR5566 | |

| Descripción | TFT-LCD Supply + DCP + VCOM Amplifier + Gate Pulse Modulator + RESET | |

| Fabricantes | Intersil | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de ISL97649AR5566 (archivo pdf) en la parte inferior de esta página. Total 21 Páginas | ||

|

No Preview Available !

DATASHEET

TFT-LCD Supply + DCP + VCOM Amplifier + Gate Pulse

Modulator + RESET

ISL97649AR5566

The ISL97649AR5566 is an Integrated Power Management IC

(PMIC) for TFT-LCDs used in notebooks, tablet PCs and monitors.

The device integrates a boost converter for generating AVDD, an

LDO for VLOGIC. VON and VOFF are generated by a charge pump

driven by the switch node of the boost. The ISL97649AR5566

also includes a VON slice circuit, reset function and a high

performance VCOM amplifier with DCP (Digitally Controlled

Potentiometer) that is used as a VCOM calibrator.

The AVDD boost converter features a 1.5A/0.18Ωboost FET with

600/1200kHz switching frequency.

The logic LDO includes a 350mA FET for driving the low voltage

needed by external digital circuitry.

The gate pulse modulator can control the gate voltage up to 30V,

and both the rate and slew delay times are selectable.

The supply monitor generates a reset signal when the system is

powered down.

It provides a programmable VCOM with I2C interface. One VCOM

amplifier is also integrated in the chip. The output of the VCOM is

powered up with the voltage at the last programmed 8-bit

EEPROM setting.

Features

• 2.5V to 5.5V input

• 1.5A, 0.18Ω integrated boost FET

• VON/VOFF supplies generated by charge pumps driven by the

boost switch node

• LDO for VLOGIC channel

• 600/1200kHz selectable switching frequency

• Integrated gate pulse modulator

• Reset signal generated by supply monitor

• Integrated VCOM amplifier

• DCP

- I2C serial interface, address: 0101000, MSB left

- Wiper position stored in 8-bit nonvolatile memory and

recalled on power-up

- Endurance, 1,000 data changes per bit

• UVLO, UVP, OVP, OCP and OTP protection

• Pb-free (RoHS compliant)

• 28 Ld 4x5 QFN

Applications

• LCD notebook, tablet and monitor

VIN

C1, 2

20µF

VIN

C32

0.1µF

VLOGIC

VLOGIC

LDO VIN

C25

1µF

C24

2.2µF

R18

3.92k

R17

8.25k

AVDD

C19

0.47µF

R9

10k

133k

R8

R7

83k

VCOM

September 11, 2015

FN8774.0

1

VIN

EN

SS

FREQ SEQUENCER

L_IN

AVDD BOOST

CONTROLLER

L1 10µH

LX

PGND

D1 C4, 5, 6

30µF

SW

R1

73.2k

AVDD

C7 AVDD

0.1µF

FB

COMP

R2 8.06k

R12 5.5k C20 15nF

D4

Q1

VOFF

L_OUT

ADJ

SCL

SDA

RSET

POS

AVDD

OUT

NEG

LDO

DCP

GPM

VCOM OP

VOLTAGE

DETECTOR

THERMAL PAD

VFLK

VGH

VDPM

CE

RE

VGHM

GPM_LO

VDIV

CD2

RESET

C11

0.1µF

AVDD

C15

1µF

C8

47nF

D2 C9

1µF

R6 1k

Z1

SW

C10

47nF

D3

C16

1µF

VON

C12

1µF

C17 1nF

C14 100pF

C28

0.1µF

R5 100k

C18

0.47µF

R14 85k

VGH GPM

R22 22k

R26 100k

VIN

OPEN

R15 115k

C26 1nF

RESET

AVDD

VGH

R16

10k

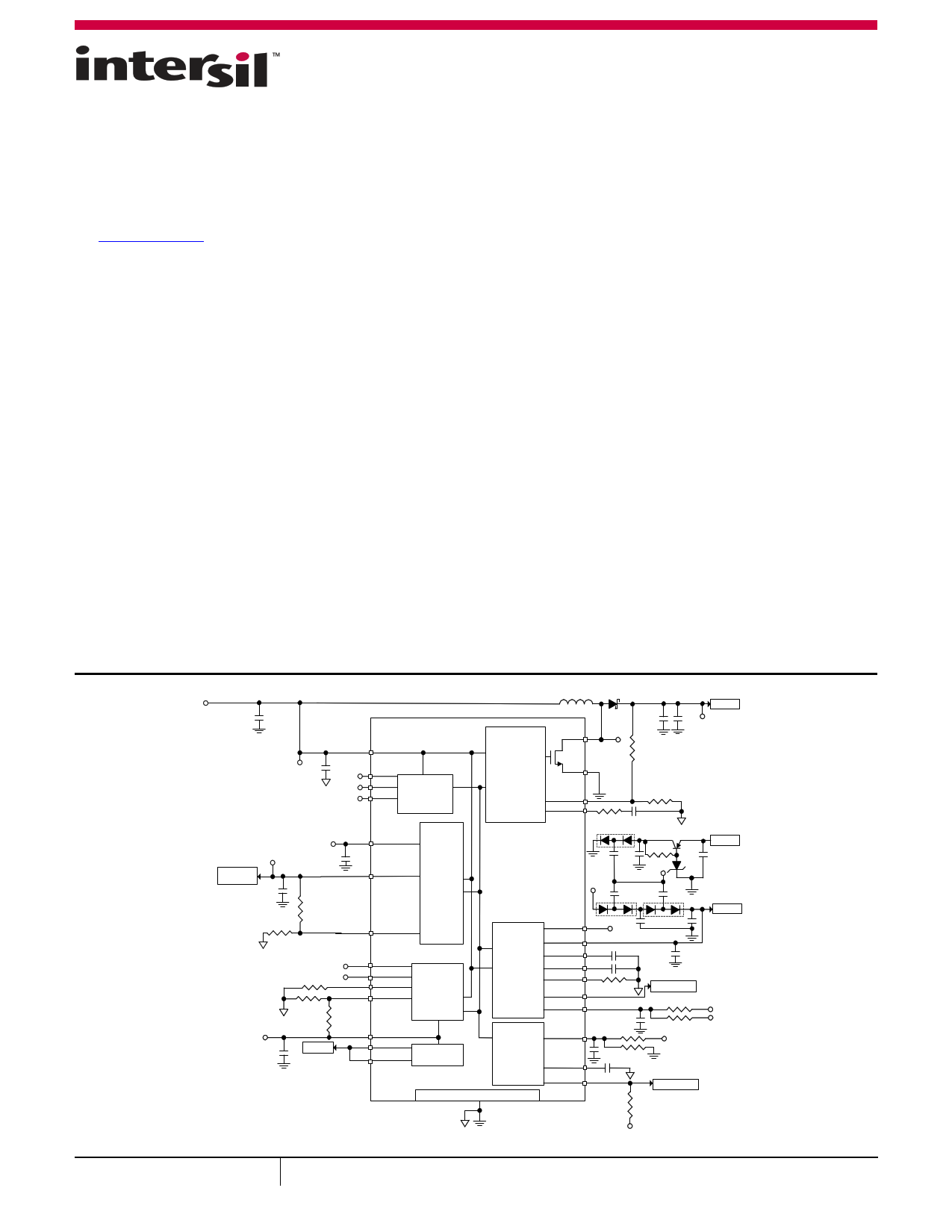

FIGURE 1. APPLICATION DIAGRAM

VLOGIC

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774 | Copyright Intersil Americas LLC 2015. All Rights Reserved

Intersil (and design) is a trademark owned by Intersil Corporation or one of its subsidiaries.

All other trademarks mentioned are the property of their respective owners.

1 page

ISL97649AR5566

Absolute Maximum Ratings

RE, VGHM, GPM_LO and VGH to GND . . . . . . . . . . . . . . . . . . . . -0.3 to +36V

LX, AVDD, POS, NEG, VOUT to GND. . . . . . . . . . . . . . . . . . . . . . . -0.3 to +18V

Voltage Between GND and PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.5V

All Other Pins to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to +6.0V

ESD Rating

Human Body Model (Tested per JESD22-A114E) . . . . . . . . . . . . . . . . 2kV

Machine Model (Tested per JESD22-A115-A) . . . . . . . . . . . . . . . . . 200V

Charged Device Model (Tested per JESD22-C101). . . . . . . . . . . . . . . 1kV

Thermal Information

Thermal Resistance (Typical)

JA (°C/W) JC (°C/W)

28 Ld 4x5 QFN Package (Notes 4, 5). . . . .

38

4.5

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

Functional Junction Temperature . . . . . . . . . . . . . . . . . . . .-40°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Lead Temperature During Soldering . . . . . . . . . . . . . . . . . . . . . . . . +260°C

Pb-free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see TB493

Recommended Operating Conditions

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5V to 5.5V

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product

reliability and result in failures not covered by warranty.

NOTES:

4. JA is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See Tech

Brief TB379.

5. For JC, the “case temp” location is the center of the exposed metal pad on the package underside.

Electrical Specifications VIN = ENABLE = 3.3V, AVDD = 8V, VLDO = 2.5V, VON = 24V, VOFF = - 6V. Boldface limits apply across the

operating temperature range, -40°C to +85°C.

SYMBOL

PARAMETER

TEST CONDITIONS

MIN TYP MAX

(Note 6) (Note 7) (Note 6) UNIT

GENERAL

VIN VIN Supply Voltage Range

IS_DIS

VIN Supply Currents when Disabled

VIN < UVLO

IS VIN Supply Currents

ENABLE = 3.3V, overdrive AVDD and VGH

IEBABLE

ENABLE Pin Current

ENABLE = 0V

LOGIC INPUT CHARACTERISTICS - ENABLE, FLK, SCL, SDA, FREQ

2.5 3.3 5.5 V

390 500 µA

0.7 1.0 mA

0 µA

VIL Low Voltage Threshold

VIH High Voltage Threshold

RIL Pull-Down Resistor

INTERNAL OSCILLATOR

Enable, FLK, FREQ

1.75

0.85

1.25

0.65

1.65

V

V

MΩ

FOSC

Switching Frequencies

AVDD BOOST REGULATOR

FREQ = low, TA = +25°C

FREQ = high, TA = +25°C

550

1100

600

1200

650

1300

kHz

kHz

DAVDD/

DIOUT

AVDD Load Regulation

50mA < ILOAD < 250mA

0.2 %

DAVDD/

DVIN

AVDD Line Regulation

ILOAD = 150mA, 2.5V < VIN < 5.5V

0.15

%

VFB

IFB

rDS(ON)

ILIM

DMAX

EFF

Feedback Voltage (VFB)

FB Input Bias Current

Switch ON-resistance

Switch Current Limit

Max Duty Cycle

LDO REGULATOR

ILOAD = 100mA, TA = +25°C

TA = +25°C

FREQ = 1.2MHz

FREQ = 1.2MHz, IAVDD = 100mA

0.792

0.8

0.808

V

100 nA

180 230 mΩ

1.125

1.5

1.875

A

80 90

%

91 %

DVLDO/

DVIN

Line Regulation

ILDO = 1mA, 3.0V < VIN1 < 5.5V

1 mV/V

Submit Document Feedback

5

FN8774.0

September 11, 2015

5 Page

ISL97649AR5566

Applications Information

Enable Control

With VIN > UVLO, only the Logic output channel is activated. All

other functions in ISL97649AR5566 are shut down when the

enable pin is pulled down. When the voltage at the enable pin

reaches H threshold, the whole chip turns on.

Frequency Selection

The ISL97649AR5566 switching frequency can be user selected

to operate at either constant 600kHz or 1.2MHz. Lower switching

frequency can save power dissipation at very light load

conditions. Also, low switching frequency more easily leads to

discontinuous conduction mode, while higher switching

frequency allows for smaller external components, such as

inductor and output capacitors, etc. Higher switching frequency

will get higher efficiency within some loading range depending

on VIN, VOUT and external components, as shown in Figure 3 on

page 9. Connecting the FREQ pin to GND sets the PWM switching

frequency to 600kHz, or connecting FREQ pin to VIN for 1.2MHz.

Soft-Start

The soft-start is provided by an internal current source to charge

the external soft-start capacitor. The ISL97649AR5566 ramps up

the current limit from 0A up to the full value, as the voltage at the

SS pin ramps from 0V to 0.8V. Hence, the soft-start time is 3.2ms

when the soft-start capacitor is 22nF, 6.8ms for 47nF and

14.5ms for 100nF.

Operation

The boost converter is a current mode PWM converter operating

at either 600kHz or 1.2MHz. It can operate in both Discontinuous

Conduction Mode (DCM) at light load and Continuous Conduction

Mode (CCM). In continuous conduction mode, current flows

continuously in the inductor during the entire switching cycle in

steady state operation. The voltage conversion ratio in

continuous current mode is given by Equation 1:

V-----BV----oI--N-o---s---t = 1-----–-1----D---

(EQ. 1)

Where D is the duty cycle of the switching MOSFET.

The boost regulator uses a summing amplifier architecture

consisting of gm stages for voltage feedback, current feedback

and slope compensation. A comparator looks at the peak

inductor current cycle-by-cycle and terminates the PWM cycle if

the current limit is reached.

An external resistor divider is required to divide the output

voltage down to the nominal reference voltage. Current drawn by

the resistor network should be limited to maintain the overall

converter efficiency. The maximum value of the resistor network

is limited by the feedback input bias current and the potential for

noise being coupled into the feedback pin. A resistor network in

the order of 60kΩ is recommended. The boost converter output

voltage is determined by Equation 2:

VBoost = R-----1--R---+--2--R-----2- VFB

(EQ. 2)

The current through the MOSFET is limited to 1.5APEAK.

This restricts the maximum output current (average) based on

Equation 3:

IOMAX = ILMT – ---2--I--L- V-V----I-O-N--

(EQ. 3)

Where IL is the peak-to-peak inductor ripple current, and is set

by Equation 4:

IL = -V---L-I--N-- -f-S--D--W----

(EQ. 4)

where fSW is the switching frequency (600kHz or 1.2MHz).

Capacitor

An input capacitor is used to suppress the voltage ripple injected

into the boost converter. The ceramic capacitor with a

capacitance larger than 10µF is recommended. The voltage

rating of the input capacitor should be larger than the maximum

input voltage. Some input capacitors are recommended in

Table 1.

TABLE 1. BOOST CONVERTER INPUT CAPACITOR RECOMMENDATION

CAPACITOR

SIZE MFG

PART NUMBER

10µF/6.3V

0603 TDK

C1608X5R0J106M

10µF/16V

1206 TDK

C3216X7R1C106M

10µF/10V

0805 Murata

GRM21BR61A106K

22µF/10V

1210 Murata

GRB32ER61A226K

Inductor

The boost inductor is a critical part that influences the output

voltage ripple, transient response, and efficiency. Values of

3.3µH to 10µH are used to match the internal slope

compensation. The inductor must be able to handle the following

average and peak currents shown in Equation 5:

ILAVG

ILPK =

= 1----I-–-O----D---

ILAVG

+

---2--I--L-

(EQ. 5)

Some inductors are recommended in Table 2 for different design

considerations.

TABLE 2. BOOST CONVERTER INDUCTOR RECOMMENDATION

DIMENSIONS

INDUCTOR (mm)

MFG

PART

NUMBER

NOTE

10µH/ 8.3x8.3x4.5 Sumida CDR8D43-100NC

4Apeak

Efficiency

Optimization

6.8µH/ 5.0x5.0x2.0 TDK PLF5020T-6R8M1R8

1.8Apeak

10µH/ 6.6x7.3x1.2 Cyntec PCME061B-100MS

2.2Apeak

PCB

space/profile

optimization

Submit Document Feedback 11

FN8774.0

September 11, 2015

11 Page | ||

| Páginas | Total 21 Páginas | |

| PDF Descargar | [ Datasheet ISL97649AR5566.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ISL97649AR5566 | TFT-LCD Supply + DCP + VCOM Amplifier + Gate Pulse Modulator + RESET | Intersil |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |